Omega Center for Sustainable Living

Project Overview

Founded in 1977, the Omega Institute is the nation's largest holistic learning center. Their mission: "To look everywhere for the most effective strategies and inspiring traditions that might help people bring more meaning and vitality into their lives." In 2006 they set out to develop a new and highly sustainable wastewater filtration facility for their 195-acre campus, which is located within one of the most important watersheds in the world, the 13,400 square-mile Hudson River basin.

The primary goal for this project was to overhaul the organization's current wastewater disposal system by using alternative methods of treatment. As part of a larger effort to educate the client's visitors, staff, and local community on innovative wastewater strategies, they decided to showcase the system in a building that houses both the primary treatment cells as well as a classroom and laboratory. In addition to using the treated water for garden irrigation and in a greywater recovery system, they use both the system and building as a teaching tool in their educational program designed around the ecological impact of their system. These classes are offered to campus visitors, area school children, university students, and other local communities.

Design & Innovation

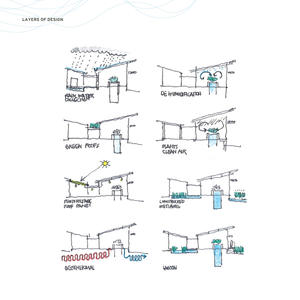

The Omega Center for Sustainable Living (OCSL) is a purposeful building and site, designed to clean water, return the clean water to the local systems, and educate users about the process. The design team selected engineered biological wastewater treatment system technologies to clean the water using the earth, plants and sunlight. The entire building and water process use site-harvested renewable energy achieving a net-zero energy system. To achieve this goal the facility had to be free of waste (volume, material, energy), organized, and carefully tuned to harvest solar energy for passive heating and lighting, using the entire mass for thermal comfort. The resultant design's simplicity and elegance suits its purpose well.

Creating an interior environment that is comfortable for people and, at the same time, fertile for the plants was critical. The result is a careful balance of passive (daylight, passive solar heating, natural ventilation) and mechanical (geothermal, fans, electric lighting) comfort systems. Plants growing in the interior lagoons required very precise solar energy levels on both their south and north exposures—the building section, windows, and skylights were carefully designed as an integrated system, meeting those needs while creating a memorable human experience.

Regional/Community Design

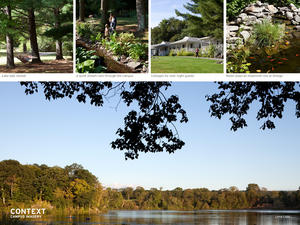

Water is a critical issue for the region. The Omega campus is located adjacent to Long Lake, which is part of a tributary system of the Hudson River. Every water system is facing challenges caused by human activities. The issues of the Hudson are well documented and numerous actions are underway to improve the river and its systems. Given the proximity to the population base surrounding New York City, the Hudson is one of the most important bodies of freshwater on the planet. The neighbors surrounding Long Lake, including Omega prior to the construction of the OCSL, are causing degradation of the lake—from agricultural runoff, landscaping chemicals, septic systems, and urban water issues.

Omega envisioned the OCSL project as a means of thinking globally and acting locally. This began with the decision to clean up and build on the former dump to ensure that leaching or other threats to the aquifer would cease. The innovative natural systems approach of reclaiming water and returning it clean to the local watershed represents a direct approach of reducing the water footprint of every individual who visits the campus, of improving the aquifer and Long Lake locally, and having similarly positive impacts on regional and global water supplies beyond.

Metrics

Land Use & Site Ecology

The campus lies within the lower Hudson River Valley watershed basin, home to one of the world’s most populous areas. The site was formerly a gravel parking lot and the remnants of a dump from a previous use. It was nearly devoid of healthy biodiversity above the ground or within. The new landscape is quite the opposite. Automobiles and waste have been replaced with deep-rooted native plants, a healthy water system, birds, insects and other species. The site is pesticide- and toxin-free.

The landscape design is regenerative of native site ecology, didactic in form, holistic in function, and above all, provides inspiring landscapes that reflect the ecological and cultural context of the campus. There are four constructed wetland cells that terrace down the southern slope adjacent to the building. As part of the wastewater recycling/treatment process, water passes through the gravel beds within these wetlands and is gradually released into subsurface areas north of the building. The overall effect is colorful and garden-like. The diverse palette of perennial plants provides habitat for a variety of birds and beneficial insects as part of the overall landscape system. Paths provide access to these spaces for learning opportunities.

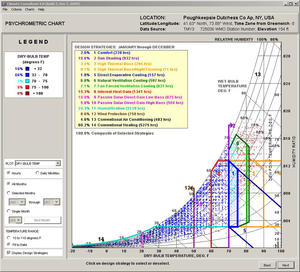

Bioclimatic Design

Located along an east-west axis, the building is oriented for optimal control of daylighting and solar heat gain. Furthermore, the building form and section evolve from the practical need to serve the plants doing the work of the wastewater treatment in the Eco Machine. Early research revealed that traditional greenhouse design, while maximizing sunlight for the plants, would not maintain a comfortable environment for workers and visitors to the facility. Recognizing that the plants would reach a light saturation point at around 30,000 lux, the team made a design goal to flatten the amount of light falling on the plants‚ surfaces during the summer months to this level in order to minimize the heat taken on by the space. (Conversely, during colder months, the amount of light will be maximized and warm the space). Solar tracking skylights were installed to aid in this effort. Future sunshades along the southern face will bounce sunlight onto the ceiling of the greenhouse, allowing for an even distribution of light and shading the lower portion of glass during the summer months. Roof materials include a combination of vegetation and recycled metal, which help to cool interior spaces, mitigating the "heat island" effect.

Light & Air

Daylighting, natural ventilation, and views are achieved through a system of operable, fixed, and solar-tracking fenestration. Operable windows are provided in each occupied space for both the health and enjoyment of guests, in addition to being part of the passive heating and cooling strategy for the building. Plants in the engineered biological wastewater treatment system remove carbon dioxide and other gases while producing oxygen—indoors and outdoors. Clerestory windows ventilate the lobby, mechanical room, and restrooms. Solar radiation heats the upper volume of air, and then natural buoyancy induces stack ventilation, which causes the air to push its way out of the open windows and pull in fresh, cooler air from lower windows in these spaces. Operable windows integrated into the south façade also allow for natural ventilation to assist in pushing hot air out of the building by channeling prevailing breezes that have been cooled while moving over the wetlands.

Building and site are integrated as a single system. The landscape produces a microclimate of clean air and beauty beneficial to the occupants. Water from the building feeds the plants and other living systems of the landscape. The two are visually connected by the transparency of each indoor space.

Metrics

Water Cycle

Water supply is provided directly from the groundwater via wells on campus. Prior to construction, water was drawn from the wells, used for multiple human activities, then piped to a septic/leach field system. The new engineered biological wastewater treatment system now returns a higher quality of water back to the earth using natural systems that see our waste as food. Aerated lagoons, one component of the system, are on display for all to see, carrying graywater through the reclamation process. At the end, the water may be used to support the needs of the building.

For potable water uses, well water is still drawn from the earth. For toilet flushing, rainwater is collected from the building’s roof. Low-flow plumbing fixtures have been installed to minimize water consumption, including waterless urinals in the men’s restroom. For all other water use on campus, blackwater and graywater are sent to the wastewater treatment lagoons and constructed wetlands for purification. By the end of this cycle that uses natural systems, cleaner water is reintroduced to the groundwater and lake.

Metrics

Energy Flows & Energy Future

Achieving net-zero energy required a design that eliminated waste and maximized the use of renewable energy resources. The building is purposely compact, organized to harvest daylight, passive heating, and cooling breezes to reduce energy needs. The insulated thermal mass of the building and the thermal mass of the water (55°F) passing through the treatment cycle are instrumental in reducing demands upon mechanical systems. During summer months the cool laboratory water has both a cooling and drying effect on the hot humid air entering the building. Efficient geothermal wells and heat pumps are utilized to provide heat for all spaces. Cooling is only provided for the classroom.

Sunlight is the primary lighting source. The shape of the building is designed to harvest sunlight via windows, skylights, and shading devices to produce appropriate, comfortable lighting without adversely affecting air temperatures. Electric lighting systems are extremely efficient and controlled to be used only when conditions mandate supplemental light.

Photovoltaic panels generate more energy than the building utilizes annually, making the OCSL a net-zero energy building. The excess energy is sold to the local utility. During evenings and certain winter periods energy is provided by the electric utility.

Metrics

Materials & Construction

The architectural expression of materials is one of simplicity and transparency and is influenced by the colors and textures of the region. No effort was made to mask the underlying nature of a material, but rather to express its unique beauty. As a pedagogical and practical measure, interior finishes were reduced or eliminated. This honest approach helped reduce the overall embodied energy of the building and minimized potential off-gassing from various construction materials.

The OCSL facility is a showcase for salvaged materials and demonstrates how easily any building can take advantage of material reuse. Reclaimed materials used on the project include dimensional lumber, plywood, interior doors, beech wood paneling, and toilet partitions. (Materials came from warehouses, schools, office buildings, and other projects). All installed wood is either from an FSC-certified forest or a reclaimed source, including the plywood roof and wall sheathing, which was salvaged from the 2009 presidential inaugural stage. Materials were also sourced to avoid "Red List" materials from the Living Building Challenge Guidelines.

During construction, 99% of metal, cardboard, rigid foam, and wood scraps were recycled. All of food waste was composted, and 100% of glass, paper, and plastic packaging waste were recycled.

Long Life, Loose Fit

Though the primary purpose of the building and site is cleaning water, its broader vision is to be a learning center that is adaptable for future pedagogical needs: a greenhouse supplying flowers for the campus and a research center dedicated to water and ecology systems. The classroom is designed for instructional classes related to water, yoga, and other programs offered on campus now and in the future. As a laboratory, the building and site are designed to embrace new technologies and emerging research. The landscape is planned as a research laboratory for native plants and water reclamation. In order to do these things the facility must be durable and live long as a result of all building systems. Materials requiring little or no maintenance were used throughout the facility due to the harsh exterior and interior (greenhouse) environments.

Inherent in the long-term view embraced by this project is the commitment to ecological wastewater treatment and renewable energy technologies. Each approach represents greater first cost investments than traditional technologies. These initial first cost investments will contribute to greater sustainability and longer lives, not only for this building, but for the Omega Campus and facilities as a whole.

Collective Wisdom & Feedback Loops

The pioneering nature of this project has left the team with many lessons from the design and construction process. Many are the result of pursuing the Living Building Challenge and many others are products of the nature of the facility. A new lesson for this project was the complexity of finding materials that not only were not on the red list but also met radius and responsible industry requirements and were affordable for the client.

Our approach was an intuitive, scientific, and experiential process. Concepts were modeled using scientific tools to measure comfort, energy, daylighting and other metrics. The team collaborated and relied upon the findings of the modeling to develop an integrated, high-performance design for the building and site. One example was using water as a tempering element to improve comfort and reduce mechanical system capacity.

The OCSL is one of the first projects completed with construction that is designed and built to meet the Living Building Challenge. Its rigorous one-year performance verification period commenced in May; operations will be carefully monitored and evaluated by the Living Building Challenge. This process will optimally result in the building performing as designed and being awarded Living Building status.

Other Information

Omega is an atypical owner. The decisions to use engineered biological wastewater treatment system technologies, renewable energy, and efficient building strategies are central to the mission of the organization. The decision to embrace those strategies, LEED Platinum certification, and the Living Building Challenge was approached without cost analysis—it was just the right thing to do.

Cost Data

Cost data in U.S. dollars as of date of completion.

-Total project cost (land excluded): $2,800,000

Within the framework of these goals, efficient cost control was a constant challenge for the project, though it was treated somewhat typically in terms of project decision-making. The owner was extremely active in the design and construction process, becoming exceptionally knowledgeable about the costs of each item. Options were evaluated and decisions were made on the cost of every major building and landscape system. This process helped the team achieve project goals with the most economical solution.

Predesign

Predesign was underway prior to the design firm’s involvement in the project; the general program was developed and the choice of engineered biological wastewater treatment system technology had been made. Through rigorous dialogue with the client, a clear vision emerged that included an expanded facility for education, a regenerative approach to the landscape, and a desire to meet the Living Building Challenge. The idea that the OCSL could be not only about cleaning the water of Omega’s campus but also have an impact beyond their boundaries began to take shape.

Design

The program was simple yet very important. Equally important was the opportunity to improve the first impression of the campus through the conversion of parking lots into gardens and creating a compact building dedicated to water. The team gathered during its first visit to the site and developed the site plan and original building concept during a two-day workshop. The concepts that emerged from that session remained intact throughout the process, though a significant change resulted as the design developed. The roof slope on the main building was reversed as a result of new information concerning solar energy needs for growing plants. In this case, the scientific process superseded our initial intuition for the massing and orientation of the building forms.

Construction

There were three notable factors regarding the construction process. The client served as general contractor, with the support of a small construction firm. The remoteness of the site made sourcing materials and specialty technology services difficult. Material requirements for the Living Building Challenge and LEED Platinum target made procurement, and therefore the overall construction process, more complicated than usual.

Operations/Maintenance

Operating a Living Building with such a specific purpose is a learning experience. The team running the facility has to learn the systems and make seasonal adjustments. If the fans stop running condensation can accumulate quickly, so quick response time is required to avoid such conditions. The shift from automatic, operable windows to manual operable windows will require greater attention in operating the facility.

Commissioning

The commissioning process is ongoing. It is the team’s expectation that, even though formal commissioning is complete, the building needs to operate through all four seasons and an annual campus cycle to fully tune the systems.

Post-Occupancy

The building is in a one-year process of measurement and verification as part of the Living Building Challenge, which requires a full year of documented net-zero operations prior to certification. The results will be available in May 2010.

Additional Images

Project Team and Contact Information

| Role on Team | First Name | Last Name | Company | Location |

|---|---|---|---|---|

| Architect | Steve | McDowell, FAIA | Berkebile Nelson Immenschuh McDowell Architects | Kansas City, MO |

| Architect | Brad | Clark | BNIM Architects | Kansas City, MO |

| Electrical, mechanical, plumbing engineer (Lighting designer) | BGR Consulting Engineers | Kansas City, MO | ||

| Energy consultant (Lighting designer) | BNIM Architects | Kansas City, MO | ||

| Civil engineer | Pierre | Brissette | Chazen Companies | |

| Landscape architect | Gerould | Wilhelm | Conservation Design Forum | Elmhurst, IL |

| Contractor | David | Sember | David Sember Construction | |

| Commissioning agent | Michael | Stritch | EME Group | New York, NY |

| John | Todd | John Todd Ecological Design, Inc. | Woods Hole, MA | |

| Michael | Ogden | Natural Systems International | Santa Fe, NM | |

| Owner/developer | Robert "Skip" | Backus | Omega Institute for Holistic Studies | Rhinebeck, NY |

| Structural engineer | David | Mar | Tipping Mar | Berkeley, CA |