Z6 House

Project Overview

The Z6 House is a single-family residence that was added to a multifamily-zoned lot with an existing duplex. It has four bedrooms and 2.5 baths. The house serves as both a residence and a model home for a line of green, modular, single-family dwellings offered by the owner's business.

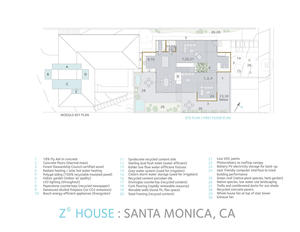

The house is constructed of factory-built modules that were erected on the site-built foundation over a period of 13 hours; the structural slab-on-grade serves as the finish floor for the first level. A roof deck offers views and a green roof with vegetation native to southern California.

Design & Innovation

A commitment to minimizing the project's ecological footprint informed all aspects of the home's design. The project team used the phrase "six zeroes" to describe the goals of the project: zero waste, zero energy, zero water, zero carbon, zero emissions, and zero ignorance.

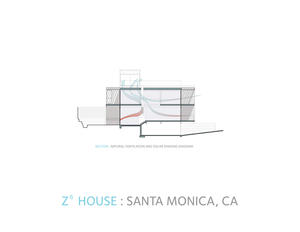

The design maximizes the opportunities of the mild, marine climate with a passive cooling strategy using cross-ventilation and a thermal chimney. A 2.4-kilowatt photovoltaic array and a solar hot-water collector take advantage of the sunny location, as does the daylighting strategy for the interior.

To create flexible interior spaces, all bedrooms have moveable wall partitions that can be opened to common areas for more space. Large exterior doors and large expanses of glass connect the inside to the outside, allowing the living space to expand to the outdoors.

Regional/Community Design

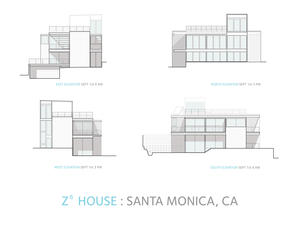

The large doors, large glazed openings, and multiple exterior decks and terraces connect the project's inside to the site and allow the living space to expand to the outdoors. This flexibility between indoor and outdoor living spaces is traditional in southern California architecture.

The house was built in a dense neighborhood with single-family and multifamily houses in the surrounding blocks. Public transportation stops within a quarter-mile of the house, and the use of bicycles for transportation is common in the neighborhood. Grocery stores, restaurants, banks, schools, parks, a theater, and other conveniences are all available within short walking distance of the house. Regardless, local code requires the house to have a two-car garage.

Metrics

Land Use & Site Ecology

The project is a single-family residence that was added to a multifamily-zoned lot with an existing duplex. Prior to construction, this portion of the site was covered in hardscape and lawn. To recreate the open feeling of the space prior to construction, the project team incorporated a green roof into the project. Plantings on the roof are native species, mostly sedums, native grasses, and rushes. The site also includes a small vegetable and herb garden. The landscaping around the house consists of newly planted native groundcover, shrubs, and trees.

Because the neighborhood was originally sited on sand dunes that were paved over for development, creating hills, the project site is sloped. Site drainage, stormwater use, and stormwater infiltration on site are important issues in this ecology. Rainwater collected from the roof, combined with stormwater diverted from site drains and swales, is stored in a cistern and used to irrigate the gardens.

Bioclimatic Design

The most important climatic issue to address for a residence in this climate is mild heating in the winter. Air-conditioning is generally not needed, but it is important to have good passive solar orientation and shading and to take advantage of natural ventilation. The breezes from the coast, from the southwest and northwest, are fairly constant and predictable.

The home is oriented 45 degrees from a north-south axis. There are operable windows and doors on the southwest, southeast, and northeast faces that provide natural ventilation. The design incorporates an open plan and two-story volume that helps the air move throughout the house. A whole-house fan located at the top of the stair tower leading to the roof helps draw hot air out of the building. The chimney effect is in evidence on a warm day.

Each of the southwest, southeast and northeast facades also have large deck overhangs to prevent solar heat gain from the summer sun. In the winter, the southeast glazing admits direct sun, which heats up the concrete floors at the first level; this warms the house into early evening on a sunny day. Glass ceilings in the upstairs bathrooms capture heat from the sun in the winter and shading devices divert the heat in the summer months.

The house has an evacuated-tube solar hot water collector. This collector runs to a heat exchanger that heats water for domestic use and for a radiant floor heating system. There is no air conditioning. The climate is dry and humidity control is not a concern. Natural ventilation and the whole house fan are effective in cooling the house.

Light & Air

As the building envelope is 73% glazing, by area, all rooms receive plenty of daylight. Operable windows or exterior sliding doors provide every room with natural ventilation and views to the exterior. Skylights bring light into the two upstairs bathrooms. The southwest, southeast, and northeast facades have operable windows and doors, while the northwest facade has a translucent insulated panel for daylight transmission in a direction without desirable views.

Protecting occupant health and comfort was among the goals for the project, so the team selected paints and sealants with low levels of volatile organic compounds (VOCs). No carpet was used, and the house features an indoor garden to improve air quality.

Metrics

Water Cycle

The 3,500-gallon water cistern sits below grade; collected water is pumped up to irrigate the roof garden. The irrigation system on the roof consists of boxes lined with an EPDM membrane and filled with evaporative-control-system chambers that help keep moisture in the planting medium, which is a mixture of sand and perlite. The bottom three inches of each box is kept moist; water is pumped up to the roof as needed to maintain this level. Excess water flows out of the boxes and back to the cistern.

The ground-level landscaping is watered with graywater from the showers, tubs, bathroom sinks, and clothes washer, via a subterranean irrigation system. All irrigation is controlled by a device that monitors humidity in the atmosphere and prevents irrigation when it is raining.

Low-flow plumbing fixtures throughout the house further reduce the home's use of potable water.

Energy Flows & Energy Future

The Z6 house has a very low energy profile in part because it has no forced-air heating or cooling. The building takes advantage of natural ventilation from the prevailing breezes, with an open plan and a whole-house fan drawing air up through the top of the home. The house was designed to optimize passive solar heating, with glazing to admit winter sun and balconies placed to shade the house from summer sun. A radiant floor heating system is powered by a solar hot water collector.

All of the appliances are Energy Star rated and the lighting system is a low energy usage LED system that is controlled by an integrated home automation system. A 2.4-kilowatt photovoltaic (PV) array above the roof acts as a shade canopy for the roof stair access. The PV array was designed to provide 60-75% of the homes energy usage, and includes includes battery storage. This, and the operable windows and doors in every room, will make the house habitable during a blackout.

Most daytime lighting is handled with natural light from skylights and floor-to-ceiling glass.

Metrics

Materials & Construction

Building the home in a factory and assembling it on site significantly reduced the project's use of material resources. In a conventional wood-framed home, 30%–40% of the materials used end up in a landfill; the construction waste for the Z6 House was 10% of that for a comparable, conventional home.

Because the goals for the project included maximizing views, daylighting, and passive solar heating, the home features large areas of glass; to maintain a high level of energy efficiency, the team selected high-performance, low-emissivity glass.

Other materials in the house were chosen based on the environmental impact of their manufacture or harvest. Wood certified according to Forest Stewardship Council (FSC) standards was used for exterior siding, exterior decking, interior wood ceilings, and millwork veneers. Cork, a rapidly renewable material, was used for the floor. The structural steel frame, countertops, and porcelain tiles include recycled content. Aggregate was used in the concrete floor slab and foundation.

Long Life, Loose Fit

The house was designed to accommodate the owner’s current and future needs. The open plan allows for flexible use of space, and the bedrooms have sliding panels that allow the rooms to be connected to or shut off from common spaces, depending on the occupants' needs. This feature allows for fluctuations in family size, including children or elderly parents needing care.

Large sliding doors connect the interior to the decks and patios, providing visual and actual extension of space. Because of its modular construction, the house could be disassembled and moved to another location, should that become necessary.

Collective Wisdom & Feedback Loops

The home was part of the LEED for Homes pilot program; the LEED Platinum rating resulted from the collaborative efforts of the architect, owner, LEED provider, consultants, subcontractors, contractor, and fabricator. Meetings with subcontractors and consultants led to innovations in the design of the heating and power systems. Inspectors from the City of Santa Monica were invited early in the process to both the site and the factory so that all parties could understand which jurisdictions inspected which parts of the project.

Participants in this project found that engaging all parties in the environmental goals from the beginning of the project generated interest and made many of the environmental goals possible.

The building has a comprehensive monitoring system that tracks the total water, graywater, and rainwater usage as well as the total energy consumption and production. A user-friendly interface was developed so the occupants can track this information in real time. The design of future homes in this product line will be adjusted in response to the performance data collected on this house.

Other Information

The project team believes that the photovoltaic system will pay for itself in energy savings in eight to ten years.

Predesign

Defining the environmental goals for the project with the owner and architect was the first, most important step. The assembly of a team of consultants and subcontractors with the correct expertise was important at this phase, especially for the in-floor heating, photovoltaics, and wastewater systems.

Design

Sun studies and a preliminary energy analysis informed the location of decks and overhangs. Sourcing materials was an ongoing effort. Early in the process, the design team educated the contractors about the goal of achieving a Platinum rating in the U.S. Green Building Council's LEED for Homes rating system.

Construction

As a modular home, the Z6 House was built in a factory, a form of construction that uses materials more efficiently than conventional construction does.

LEED documentation was new to this factory and therefore an unusual aspect of the construction.

Operations/Maintenance

A comprehensive owner’s manual was provided with the home. The owner was deeply involved in all aspects of the design and construction, and has an appreciation of the home's systems.

Post-Occupancy

The owner of the residence has installed a monitoring system that tracks the performance of the photovoltaic array and solar hot-water collector as well as the building's use of water and energy.

Additional Images

Project Team and Contact Information

| Role on Team | First Name | Last Name | Company | Location |

|---|---|---|---|---|

| Owner/developer | Steve | Glenn | LivingHomes, LLC | Santa Monica, CA |

| Project manager | Daniel | Cunningham | LivingHomes, LLC | Santa Monica, CA |

| Environmental building consultant | Ann | Edminster | Design AVEnues | Pacifica, CA |

| Energy consultant | Vernon | Crawford | Davis Energy Group | Davis, CA |

| Structural engineer | Bud | Brown | Reiss-Brown-Ekmekji, Inc. | Los Angeles, CA |

| Module fabricator | Ed | Feser | Profile Structures, Inc. | Santa Fe Springs, CA |

| Contractor | Bruce | Campbell | Hinerfeld-Ward, Inc. | West Los Angeles, CA |

| Landscape designer | Rich | Grigsby | The Great Outdoors Landscape Design & Construction | Topanga, CA |

| Graywater and rainwater system designer | Bill | Wilson | Bill Wilson Environmental Planning | Mill Valley, CA |

| Interior designer | Heidi | Toll | Heidi Toll Design | Sherman Oaks, CA |