Global Ecology Research Center

Project Overview

Global Ecology Research Center at Stanford University is an extremely low-energy laboratory and office building for the Carnegie Institution of Washington. The mission of the new Department of Global Ecology is to conduct basic research on the interactions between the earth's ecosystems, land, atmosphere, and oceans.

This project unified several buildings and activated spaces on a site that the Carnegie Institution has occupied since 1928, improving contact and circulation between two departments and creating an outdoor collaboration space.

Design & Innovation

From the Global Ecology researchers' perspective, the most pressing environmental issues are global climate change, biodiversity, and water issues. The client encouraged the design team to reduce carbon impacts and address biodiversity and water issues while providing laboratory and research spaces that meet the highest standards of comfort and performance. This focus resulted in a 72% reduction in carbon emissions associated with building operation and a 50% reduction in embodied carbon for building materials.

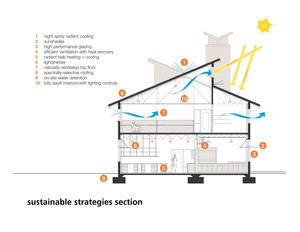

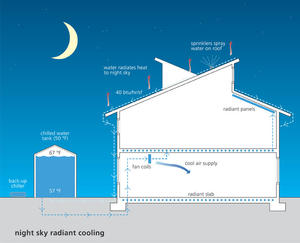

Proper orientation, exceptional daylighting, sunshading, and natural ventilation set the stage for innovative mechanical systems. A "night sky" radiant cooling system demonstrates the same principles of radiant heat loss to deep space in which the researchers are investigating. An evaporative katabatic (downdraft) cooling tower serves as an iconic focal point, while tempering an indoor/outdoor lobby and collaboration space.

The team also aggressively pursued habitat- and water-conservation goals. The exterior wood cladding is salvaged wine-cask redwood, the interior wood and veneers are FSC-certified domestic ash, tables in the conference room and lobby were made from trees salvaged from a nearby municipal yard, workstation tabletops were made from salvaged doors, and recycled aggregate substituted for about 20% of site concrete aggregate. Water use is reduced by one-third through no-irrigation landscaping, dual-flush toilets, a waterless urinal, and low-flow sinks.

Regional/Community Design

This project provided an opportunity to transform what was once an uninviting public space into an active core for the Carnegie campus. The vertical cool tower doubles as an orientation device that announces the importance of this research center as it draws visitors into the new courtyard.

Two potential sites were left over after 70 years of piecemeal development serving the Department of Plant Biology. Rather than build on a mature oak woodland in the front of the site, the design team chose to redevelop the more difficult rear site that had served as a paved utility zone for decades. The new buildings were sited to form an open courtyard with existing laboratory buildings, enhancing circulation while maintaining open space used as an agricultural research zone and allowing for future expansion of the Department of Global Ecology. Old greenhouses were reused off site, site concrete was recycled, and irrigated turf was removed.

The courtyard paving extends to the street to invite walkers and bikers to the center, supporting Stanford's pedestrian- and bike-friendly culture. A bike parking area is located on the courtyard, and showers are available in an adjacent building. Approximately one-third of the building's occupants (32%) use transit options other than single-occupancy vehicles on a regular basis. To accommodate the expected 45-person occupancy of the building, 17 parking spaces were added to a lot shared by the Department of Plant Biology and the Department of Global Ecology.

Metrics

Land Use & Site Ecology

Water use is a concern in this arid climate. Accordingly, the design team focused on limiting site water use, reducing stormwater runoff to San Francisco Bay and promoting aquifer recharge.

A native oak woodland habitat—including perennial grasses, chaparral and two species of oak—is developing without the use of a permanent irrigation system. The oak woodland will serve as critical native habitat for local fauna. The knowledgeable client’s participation was encouraged, thus inspiring students, faculty and other volunteers to organize “planting parties” to perform all of the planting. This personal connection has helped promote proper care for the landscape over time.

Bioclimatic Design

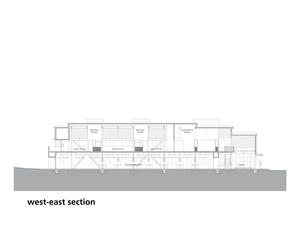

The initial design concept suggested a fatter building with a long east elevation to define a new courtyard and circulation spine. To maximize orientation efficiencies, we lengthened and rotated the building. The result is a narrow, forty-foot wide building facing directly to the south and north, which maximizes daylighting, sunshading, and ventilation opportunities.

An indoor/outdoor lobby space in turn serves to anchor the building on the courtyard. Large vertical bi-fold doors open the lobby to the landscape, allowing spaces to merge and the interior space to be passively conditioned. The sunny and dry Palo Alto climate, where the hottest days are clear with low humidity, is ideal for the Katabatic Cool Tower serving the lobby and for Night Sky radiant cooling.

All non-lab spaces have operable windows and are designed for natural ventilation. Casement windows open to the north to enhance ventilation from prevailing NW breezes. The operable clerestory height encourages stack effect ventilation on windless days. The toilet exhaust fans ensure a baseline ventilation rate when windows are closed. Natural ventilation works well with radiant heating and cooling since thermal comfort is less dependent on air temperature.

Light & Air

The design of the Global Ecology Center emphasizes daylight, exposed structure and systems for architectural character, and the minimal use of finishes.

Daylight serves as the building's primary task light and provides all of the light required for the majority of the day. The narrow building footprint (40 ft) and effective orientation, coupled with exterior solar shading allow controlled daylight, creating a space that is intimately tied to diurnal cycles with superior visual comfort. Light enters the space from two directions, providing balanced, diffuse light with direct views to the outside from all workspaces.

Direct-indirect pendants provide ambient electric lighting; important wall surfaces also washed with light. A single high-output T-5 fixture serves each lab module, supplementing the movable under-shelf task lights. Most of the lighting has occupancy sensors and is dimmed with photo-controls when daylight is sufficient.

Paints and adhesives with low emissions of volatile organic compounds (VOCs) were used throughout. Low-pile carpeting was also used. All of the air that enters the laboratory passes through 85% efficient filters. Many of the laboratory areas have HEPA filtration systems. Several occupants prefer to work in the lab areas during hay-fever season due to their excellent air quality.

The non-lab spaces all have operable windows and are designed for natural ventilation. The roof slopes up to south-facing clerestories, and casement windows open to the west to enhance ventilation from prevailing northwest breezes. The height of the clerestories encourages stack-effect ventilation on windless days. The restroom exhaust fans ensure adequate ventilation even when windows are closed. Since thermal comfort is less dependent on air temperature with radiant heating and cooling systems than with other systems, natural ventilation was well suited to this project.

Metrics

Water Cycle

Water serves as the conduit for the building's "night sky" system, a low-energy cooling system that allows a 50% reduction in water use compared to a conventional, water-cooled chiller. Water also provides energy- and water-efficient cooling in the katabatic cooling tower and serves as a highly efficient medium for heat transfer in the radiant floor and ceiling systems.

More conventional water-efficient fixtures such as low-flow sinks with automatic sensors and dual-flush toilets were installed; a waterless urinal is still awaiting county approval.

The no-irrigation, native landscape design saves an estimated 20,000 gallons of water each year, compared to conventional landscaping. Existing turfgrass was replaced with native grasses as part of the landscape plan. Manual irrigation during the first year helped establish the native plantings which are perfectly suited to the region's long summer dry season.

Bioswales constructed along three sides of the building site slow runoff and encourage infiltration and aquifer recharge. Rainwater from greenhouses and a warehouse are discharged into swales. Impermeable surfaces were minimized and paved areas shaded to reduce heat island effects. All rainwater that falls on the roof is collected in the thermal storage tank to be utilized during the heating season.

Energy Flows & Energy Future

The Center's functions are zoned so that lab areas receive high levels of ventilation and cooling, while the remaining areas are naturally ventilated. Daylighting, plug-load reduction, and building size reduction also contribute to the Center's efficiency. The building exceeds California's Title 24 energy code by an estimated 63%.

However, since the Carnegie Institute was more interested lowering the building's carbon emissions, the embodied carbon emissions of building materials as well as emissions tied to energy use were tracked. The energy-related carbon emissions were found to be 72% lower than they would be in a conventional design.

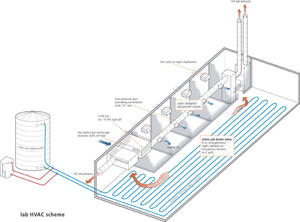

Central to the building's energy performance is a set of highly efficient mechanical systems that have never before been used in a laboratory building.

Heating and Cooling

The core of the heating and cooling system for both the laboratory and office zones is a simple, elegant, and innovative hydronic system that provides hot water (for heating) and chilled water to the building.

Chilled water for cooling is produced with the night sky system, eliminating air conditioning compressor loads that drive the peak energy load in California. A thin film of water is sprayed on the roof at night. The water is cooled through radiation to cold, deep space and stored in an insulated 12,000-gallon tank. Chilled water from the rooftop is supplied during the day at 55*F to 60*F using only 0.04 kW/ton, or 90% less energy than a chiller. The radiant cooling system uses pumps and pipes to move cool water through the building. Fans are then used solely for ventilation, saving over 70% of fan energy. Careful sunshading and R-20 rigid roof insulation reduce cooling loads.

Ventilation

Office spaces are equipped with operable windows for occupant-controlled natural ventilation. The roof slopes up to south-facing operable clerestories, and casement windows open to the west to enhance ventilation from prevailing northwest breezes. The height of the clerestories encourages stack-effect ventilation on windless days. Thermostats report indoor and outdoor temperatures, allowing occupants to make intelligent decisions about opening the windows.

In the laboratory areas, where more ventilation is need, low-face-velocity air handlers and low-pressure-drop design were used. Fan power is directly proportional to an air-handling system's resistance to flow or pressure drop. In this building, the supply-air-handling system has a total static pressure of 2.0 inches, compared to a typical 5.0 inches. This adjustment allowed for a smaller fan to be installed, resulting in 50% fan energy savings, compared to a typical system.

Cascading air flows are used for laboratory ventilation. In order to reduce the amount of outside air required, air is supplied to noncritical laboratory areas (those with no chemical use), and then cascaded through critical areas (fume-hood rooms) before being exhausted. This reduces the total air flow by approximately 20%, thus reducing the energy required for ventilation. At night, ventilation rates are lowered somewhat if spaces are not in use.

Lighting

Daylight serves as the center's primary task lighting and provides all of the light required for the majority of the day. Ambient electric lighting is provided by direct-indirect pendants, and important wall surfaces are also washed with light. Each lab module is served by a fixture that uses a high-output T5 lamp, along with movable under-shelf task lights. Most lighting has occupancy sensors and is dimmed with photo-controls when daylight is sufficient.

Energy security

Peak energy demand was reduced by shifting 4,000 ft² of program space, including a number of -80*C freezers, from the lab building into a separate semi-conditioned warehouse. This significantly reduced the size of the energy-intensive lab area and avoided the heat load of the freezers in those spaces. (Energy use for those warehouses is not included in the energy simulation.)

The datacenter is provided with full air-side economization for backup cooling in lieu of a traditional redundant compressor-based cooling system.

The lab required a back-up generator that keeps essential functions running during power outages. Combined with adequate daylight throughout and natural ventilation at the offices, the building can operate quite functionally during a blackout. Electricity is provided by the very efficient Stanford cogeneration plant located one block away. A photovoltaic array added to an adjacent building during construction as a separate project is not included in the energy calculations for this project.

Metrics

Materials & Construction

The project's embodied carbon emissions were reduced by 43% primarily through the substitution of flyash for over half of the cement in nearly all of the concrete.

Finish materials were kept to a minimum. exposed acoustic deck ceilings, radiant integrally-colored concrete floors (ground down in the lobby to expose the aggregate), and exposed steel trusses and columns were left exposed, providing much of the material character.

Salvaged materials reduced virgin material use and added narrative character to the project. Exterior redwood siding was salvaged from decommissioned Sebastiani Vineyards wine vats. Due to the tight-grained quality of this old-growth wood, no sealer or paint was necessary as a preservative, reducing first cost and maintenance over time and helping to pay for the higher quality wood. Tables in the conference room and lobby were milled down and finished from trees salvaged from a nearby municipal yard. Workstation tabletops were derived from salvaged doors donated by the contractor. One-fourth of the casework and all lab sink faucets were salvaged. Recycled aggregate substituted for 20% of site concrete aggregate.

All non-salvaged wood in the building, including doors, new casework, trim, light shelves and railings is domestic ash certified according to Forest Stewardship Council (FSC) standards.

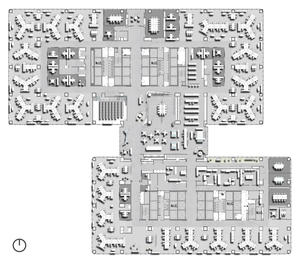

Long Life, Loose Fit

The research program requires flexibility over the short and long term. Researchers split their time equally among the field, their offices, and the lab. Therefore, all spaces were designed to allow for expansion and contraction of research teams and informal space sharing. Strategies include a standardized lab layout with movable benches and shelving and an open office plan instead of shared grad student offices as initially requested.

The research building was designed for a 100-year service life (warehouses and greenhouses were designed for 50-year life spans). A clear-span structure on the second floor will accommodate changes to the building over time. Windows, roofing, and flashing were designed so that their disassembly would not affect adjacent finishes. Redwood siding is attached with exposed screws to permit future salvage. Indoors, individual carpet tiles can easily be replaced if they are damaged.

Open ceilings in the laboratory and an exposed steel structure allow for easy reconfiguration of services and spaces as needs change.

Early programming efforts allowed a 36% reduction in building floor area. Workshop space, storage, and much of the heat-producing equipment are housed in an adjacent warehouse, reducing the need for conditioned, finished space and heat loads in the lab

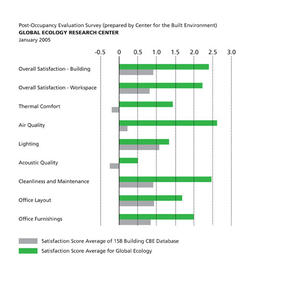

Collective Wisdom & Feedback Loops

A post-occupancy study by the Center for the Built Environment at Berkeley (CBE) ranked the project in the 99th percentile for occupant satisfaction, as compared to the database. Occupants are responding to the unusually high levels of thermal, visual, and acoustic comfort which are integral to the energy strategies.

Other lessons learned include:

-Sunlight reflecting from adjacent greenhouses into north-facing windows created uncomfortable glare at some workstations.

-To avoid adding shades (that would block daylight), a window film was installed on the lower third of this glazing.

-The photo-sensor light dimmers were difficult to commission (a bug in the manufacturer’s software prematurely stopped lamp burn-in).

-The design team made extensive efforts to reduce embodied carbon emissions, but did not foresee the contractor’s use of a temporary working concrete slab on portions of the site, which added to material quantities.

-The 50% flyash concrete mixes in some thin topping slabs didn’t produce adequate heat of hydration in cold weather for timely finishing.

-The natural resin pavement did not harden adequately in places.

-Testing indicated that high-volume flyash concrete can be cured conventionally with a curing compound instead of through wet curing.

Other Information

The project was privately funded by the Carnegie Institution of Washington. Part of the funding came from foundations that support the mission of the Department of Global Ecology.

Financing Mechanisms

-Grant: Private (foundation)

-Procurement process: Design-bid-build

Cost Data

Cost data in U.S. dollars as of date of completion.

-Total project cost (land excluded): $4,050,673

-Hard cost: $410 per sq foot ($4,400 per sq meter)

-site work: $39 per sq foot ($420 per sq meter)

-construction: $371 per sq foot ($3,990 per sq meter)

The client’s construction and operational budgets derive from the same source, so payback due to energy cost savings allowed for some modest initial cost premiums. Many of the upgrades in building systems were offset by reductions in first costs for ductwork, ceilings, chillers, etc. The payback for the green features is estimated to be between two and five years. The building is designed to last 100 years, so significant energy cost savings are expected over time.

Predesign

After selecting the design team, the client commissioned a feasibility study of the building's program to determine whether it fit within the proposed project budget. The initial space allocation stretched the proposed budget, so the team made several design decisions to reduce floor area.

At this time, the team chose to develop a two-story building to reduce the amount of site area required. The required laboratory area was approximately equal to the area of all other spaces, so this provided a straightforward rationale for dividing the program onto two floors. This division had several significant advantages, including encouraging interaction among building occupants. Whereas locating the offices inside the individual labs might have led the scientists to spend hours at a time in private, separating these functions requires the researchers to circulate through the public spaces, where they are more likely to encounter and interact with their colleagues. The labs also have dramatically different ventilation and cooling requirements than the other spaces, and the divided plan allowed them to be handled separately.

Design

The building and site design developed out of an exemplary integrated design process. All members of the design team attended the initial meetings, providing expertise that shaped the form and character of the project. Elements such as the night sky system and cooling tower required full integration of mechanical and architectural design and the appreciation of a client who embraced the sound scientific principles of these unique building systems.

The process took about one year working closely with the head of the new department and a small design committee.

Construction

The client selected a contractor halfway through the design process for assistance with cost estimating and constructability review. The project was constructed in two phases, each negotiated with a different general contractor and bid to a select group of subcontractors. The first phase included only the greenhouses and some sitework, while the second phase involved the research building, warehouse, and final sitework. The contractor’s enthusiasm for learning about sustainability led to a smooth process and a project which came in on budget. An independent construction manager assisted the client with project management.

Operations/Maintenance

The Carnegie Institution employs full-time maintenance staff trained in the unique operational aspects of the building.

Commissioning

The commissioning effort was shared between the client’s in-house technicians and the design team. Due to the unique nature of the building systems a higher than normal level of involvement in fine-tuning the project was expected and has been required. Refinements in the cooling-tower spraying, for example, were designed and implemented by staff researchers.

Post-Occupancy

The design team and client collect data and monitor the energy systems. During the hottest days of the first summer, the building held steady at approximately 76°F and occupants reported satisfactory comfort.

A post-occupancy study for the Center for the Built Environment (CBE) at the University of California at Berkeley documented high occupant satisfaction across a range of categories, as compared to the 158-building CBE database. On a scale of –3 to 3, the Global Ecology Center scored at 2.39 (compared to an average of 0.91) for overall building satisfaction. Thermal comfort scored 1.43 (compared to an average of –0.20), and air quality scored 2.61 (compared to an average of 0.22). Overall, the project placed second highest out of the 158 buildings studied.