EpiCenter, Artists For Humanity

Project Overview

Artists For Humanity (AFH) was founded in 1991 with a mission to bridge economic, racial, and social divisions and provide underserved youth with the keys to self-sufficiency through paid employment in the arts. Its new urban headquarters, the EpiCenter, provides fine and commercial art studios and a 5000 ft2 (465 m2) gallery space used to show student art; the gallery is also rented out for events.

The founder of AFH, Susan Rodgerson, saw the building project as an extension of the organization, with its social mission at the heart of the design principles. As the organization is invested in the education and empowerment of young people, so the building is designed to model environmental stewardship.

Design & Innovation

The decision to build green came from the youth of AFH, and was a natural outgrowth of the agency's work with inner-city teens as they learn about art and themselves and strive for self-sufficiency.

The EpiCenter is a simple, functional building that achieves the highest levels of sustainability on a tight budget. The building uses energy and water efficiently, incorporates recycled materials, makes full use of natural daylight, and promotes the health of its occupants. The EpiCenter also offers an opportunity to build public awareness of sustainable, economic, and environmental principles among the immediate community and beyond.

The project includes several notable green design aspects:

-A 49-kilowatt roof mounted, grid-connected photovoltaic array, currently the largest PV array in Boston, provides renewable energy for the building;

-A super-efficient envelope, including operable, low-emissivity, high-performance windows, reduces heating and cooling loads;

-Natural ventilation is used instead of air-conditioning;

-South-facing windows provide passive-solar heat gain and daylighting;

-Open, unobstructed interior spaces allow for effective daylighting;

-Energy-efficient lighting is coupled with daylight dimming and automated controls;

-The efficient mechanical system includes a heat-recovery system;

-Many building materials were salvaged and reused;

-Many building materials include high recycled content; and

-Rainwater is harvested and stored for landscape irrigation

Regional/Community Design

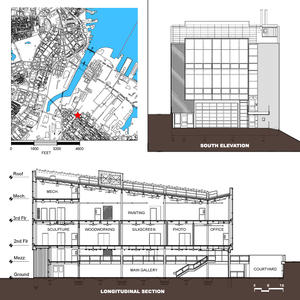

Site selection was important; AFH wanted its new building to provide a visible identity in a prominent location that would call attention to its mission of empowering urban youth.

The selected site is in a transitional area between a mostly working class residential neighborhood and a rapidly transforming mixed-use waterfront district with new high-rise offices and hotels. The site had been in industrial use for 100 years and required remediation for lead and asbestos contamination. Nearby, the Fort Point Channel Arts District is home to the largest artists' community in New England, a large resource for AFH.

Important to urban teens without cars, the site is easily reachable by public transportation from most areas of Boston. Four bus lines stop within 1/4 mile of the building, and a subway station is only 1/2 mile away. The limited parking provided on site is in keeping with the City of Boston's goal to reduce traffic inflow by limiting the creation of new parking spaces in the downtown area. Ten bicycle stalls and two showers are provided for employees and visitors.

Metrics

Land Use & Site Ecology

AFH staff and students were determined to find a central urban site for the EpiCenter. Economically, this meant that the site would be small, built to the property lines, and have little open space. Ecologically, it meant that the site would be in a highly developed area.

Because of the industrial character of the area around the selected site, there is little permeable ground nearby and almost no vegetation, wild or planted. The abutting properties are factories and asphalt parking lots, and the site required remediation for both lead and asbestos.

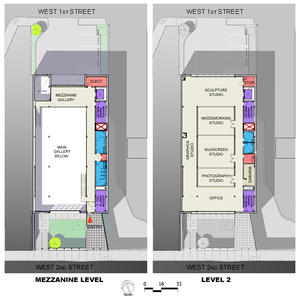

A substantial grade change over the length of the site and an old granite foundation wall unearthed during the course of excavation provided the opportunity to create a green space at the south end of the building, below street level. The courtyard provides a much-needed outdoor area that is protected from traffic noise, shaded and cool in the summer, and shielded from the wind in the winter. When weather allows, a 24-foot-wide garage door rolls open into the ceiling, connecting the courtyard to the interior of the building and letting light and air flow into the space.

Rainwater, collected from the roof, is channeled through a transparent drain pipe which runs through the gallery into a holding tank to serve the irrigation needs of the grass courtyard.

Bioclimatic Design

The site is narrow, stretching from north to south. To maximize square footage, the building footprint filled the width of the site, from the east lot line to the west lot line. This meant, per building code, no east- or west-facing windows, which energy modeling revealed was a fortunate configuration because east- or west-facing windows would have allowed undesirable solar heat gain in summer. Instead, the concentration of windows on the south side of the building provides for the deep penetration of warming sunlight in the winter. Large floor-to-floor heights, 12 and 18 feet, allow daylight to penetrate deep into the building.

The photovoltaic array played a large role in determining the shape of the building. The entire roof was sloped to the south for optimal solar gain. Operable windows at both ends of the building are placed to capture and direct the prevailing breeze in the summer.

Light & Air

The first floor gallery entrance is a functional overhead door that connects the large space to a sunken urban garden, bringing both light and ventilation to the space.

Daylight

Maximum glazing is provided on the north and south facades. Diffuse light, ideal for artwork, penetrates deep into the building from the north year-round. Sunlight from the south penetrates deep into the building in the winter for solar gain and is controlled by blinds in the summer. Transparent and translucent interior walls allow daylight from north and south to penetrate interior studios and allow views to the outside.

Ventilation

The building uses no refrigerant-based cooling.

Summer: At night the windows are opened and the ventilation system pulls cool air through the building, removing the day’s heat. In the morning, occupants close windows to retain cool air. The heat recovery unit (HRU) provides fresh air while excluding heat. When additional ventilation is desired, the night ventilation shaft and operable windows on the north and south facades provide natural ventilation. This can be supplemented by ceiling fans. A separate exhaust system pulls fresh air though the interior studios on the second floor. Fans that flush out air at night can be used during the day to supplement air movement through the building.

Winter: The HRU provides fresh air while retaining heat. A separate exhaust system pulls fresh air though the three enclosed studios on the second floor. Ceiling fans provide destratification.

Construction IAQ

A construction indoor air quality plan was followed. A two-week building flushout with MERV-13 filters was conducted with 100% outside air. New MERV-13 filters were installed following the flushout.

Metrics

Water Cycle

Beyond the already demanding requirements of the local building code, two main strategies for water conservation were employed.

Since art activities in the building tend to generate a higher than average amount of hand and equipment washing, one strategy for conservation was to install low-flow (0.5 gallons per minute) faucets that limit flow to 15 seconds for each activation. This is calculated to save 1/2 gallon per use over a standard flow, non-metered faucet. Over the course of a year it should save 30% on water use. The second strategy is to conserve rainwater harvested from the roof. The water is stored in a 1,500-gallon, underground storage tank and is designated for use to maintain the landscaping in the courtyard; excess water flows into the site stormwater management system. A glass pipe incorporated into the roof drainage system and visible in the main gallery promotes awareness of the need for efficient water use by providing a visual reminder of the harvested rainwater. There is no other irrigation system and the users are dedicated to the concept of water conservation.

Energy Flows & Energy Future

The EpiCenter was designed to use less than half the overall energy of a similar building designed in minimal compliance with ASHRAE 90.1-1999. Cost savings are estimated to be about 80% before taking into consideration onsite photovoltaic power. The most significant contributors to these savings were the elimination of mechanical cooling and very high lighting efficiency.

Energy losses through walls and roof were reduced by a combination of envelope improvements, ventilation efficiency, and air sealing. Distribution savings were achieved by using hydronic heat distribution and small tightly sealed ducts for heat recovery ventilation distribution. Finally, there are significant equipment energy savings through the choice of high performance boilers, efficient domestic water heaters, and variable-speed drives on pumps and fans.

Cooling

The cooling load was reduced with an efficient building envelope and shading of the roof by the PV array, which minimizes solar gain. The natural ventilation system takes advantage of Boston's relatively cool climate by using exhaust fans to cool the building at night. For daytime comfort, ceiling fans and operable windows are employed throughout the building.

Refrigerant-based cooling (air-conditioning) was eliminated, saving over 275,000 kilowatt-hours in electric energy each year, representing a 65% reduction in total electricity use.

Lighting

The building takes advantage of its north-south orientation with a high concentration of windows on the southern side of the building. These allow daylight to penetrate deep into the building without unwanted solar heat gain. Large floor-to-floor heights also facilitate daylighting.

The lighting system primarily uses fluorescent T-8 fixtures and employs daylight dimming controls and automatic shut-off to reduce the peak electric load. The result is an estimated 78% reduction in the lighting load relative to an ASHRAE 90.1-1999 base case. Lighting improvements save energy and reduce cooling loads but increase heating loads.

Photovoltaics

The 45-kilowatt peak photovoltaic (PV) system, which played a large role in determining the shape of the building, will produce roughly 58 MWh of electricity per year. The system is connected to the utility electric grid; no battery storage will be used. All of the power will be used immediately or sold back to the grid. In the event of a blackout, however, the power generated can be used directly by the building.

Although more electricity is produced in summer than winter, over the course of the year the electricity production promises to be greater than that used. Since electric rates are higher from June to September, the electricity produced by the PV array offsets the most expensive energy costs. The building produces 156% of its electrical energy on-site (32% of its total energy needs). Because electricity is more expensive than other forms of energy, the surplus electricity sold back to the grid will typically pay for the rest of the EpiCenter's energy costs.

Metrics

Materials & Construction

The studios at the AFH EpiCenter are filled with items scrounged from basements, trash piles, and thrift stores and re-purposed by enthusiastic, artistic endeavor. The guardrail system is fabricated out of windshields from junked police cars and taxis. An exterior railing uses abandoned train rails salvaged from the street during utility work for the project. These examples reinforce AFH's mission to teach students that they can transform the everyday objects around them into art.

The simplicity and industrial nature of the building dictate that the majority of the materials are contained in its structure and the exterior envelope. The structural steel and the stainless steel siding were selected for their high recycled content and because they are 100% recyclable should the building ever change. Recycled content was also required in the concrete which serves as both structure and, once sealed and polished, as a durable finished floor in most of the spaces. To protect the indoor air quality, all interior paints and sealants were selected for their low VOC content.

Long Life, Loose Fit

Because AFH is made up of a dynamic group of artists, programs and curricula change frequently. So the new space needed to be flexible, changeable, and upgradable for the expected building life of at least 50 years. To that end, most studios are designed for multiple uses. All interior partitions are demountable for relocation. Most are translucent to allow daylight into interior rooms wherever they are installed.

Electrical systems, computer networking, and audio-visual wiring were left exposed, not buried in walls or ceilings, to accommodate changes and advances in technology.

The main gallery space, dedicated to showcasing student work, is also used as a function space that can be rented out to house special events and corporate meetings, providing income for AFH and exposing a wider audience to the agency’s mission and student art. The decision to install a large overhead door at the gallery level also works to flexibility; it allows for easy, direct coming and going for the various events without disturbing student routines. When the door is opened during events, the outside and inside become fluidly connected to one another, the street, and the community.

Collective Wisdom & Feedback Loops

The EpiCenter demonstrates that green buildings attract broad public interest. The building has become a national model for budget-based sustainable design. Conferences and tours have included builders, architects, public officials, brownfield redevelopment experts, and green building specialists.

The building also shows that green design does not have to be expensive. Funding for the photovoltaic array was underwritten by the Massachusetts Technology Collaborative, and many of the other sustainable features cost little or no more than standard materials and methods. Most will pay for any cost differential in savings on utilities or in comfort, health, and productivity of the occupants.

The automated light-control system, which is an important part of the building’s energy performance design, is complex. The sophistication of such a system needs to be matched with the professional training of the maintenance staff and users to be truly efficient.

Other Information

Beginning in 2001, AFH raised more than $5 million from individuals, foundations, corporations, and in-kind support.

A $520,000 grant from the Massachusetts Technology Collaborative and a $200,000 grant from the utility NSTAR provided major assistance in funding the design, installation, and monitoring of the photovoltaic system. Two local utility incentive programs covered 90% of the incremental costs for the high-efficiency building envelope, equipment, lighting, and controls.

Within a year of occupancy, the EpiCenter had significantly increased program income, with gallery bookings for at least one corporate or non-profit event per week, well exceeding its income projections. It is important to note that gallery rentals provide a captive audience for the young people’s work, which stimulates commissions for other design and fine-art services and thereby leads to corporate subscriber opportunities and more program income. Expanded youth participation will ensure that AFH will have the products and staff to meet the heavier demand for work.

Financing Mechanisms

Grant: Private (foundation), Public agency

Cost Data

Cost data in U.S. dollars as of date of completion.

-Total project cost (land excluded): $4,300,000

The total energy cost for a base case building in minimal compliance with the ASHRAE 90.1-1999 energy standard would be on the order of $3.00 per square foot, or nearly $68,000 per year. The total estimated energy cost for the EpiCenter is $0.56 per square foot, or $12,732 per year; this represents a cost savings of 82%. The peak demand for the building is also dramatically reduced: demand charges and the need for utility peak power are reduced by 62% in the most extreme conditions. Demand charges of approximately $11.10 per kilowatt over the minimum 10 kilowatts are included in the costs.

The total construction cost for the EpiCenter was $4.3 million, or $183 per square foot. Utility incentives and grants from the Massachusetts Green Buildings Initiative reduced the building cost to a final cost of $168 per square foot. The cost of the photovoltaic (PV) system, at $8.27 per peak watt, is included in that total. With a grant covering 70% of the capital costs of the PV system, AFH should obtain a positive cash flow on this investment within 5 years.

The natural ventilation system cost less than a typical air-conditioning system, so the payback for this feature was immediate.

Predesign

AFH initiated a capital campaign in June 2000 and began searching for an appropriate project site in the Fort Point neighborhood. The site at 100 West Second Street was purchased on June 20, 2001. AFH originally planned to retrofit the existing building, an abandoned livery, with renewable technologies, but further research revealed that this approach was not cost effective or structurally feasible.

Design

A collaborative design process began with a series of workshops involving the AFH staff, students, and the professional design team. The design concept evolved through a series of workshops with staff and students; all expressed a strong desire for an iconic building, one that would exhibit their identity as a cutting-edge, socially conscious, activist, and community-focused organization. They wanted a headquarters that would be a strong and memorable presence in South Boston and notable within the larger context of the city of Boston. The design concept had to be clear, simple, functional, strong, and green to the highest level of LEED certification—and affordable.

To facilitate the exchange of information and ideas, a former student who was also a founding AFH staff member and recent RISD architectural graduate worked at the architect’s offices during the design process. Three afternoons a week he also taught students at AFH about architectural design. The student activities included building a model of the project that was used in community presentations, making daylight study models, and designing their own versions of the project. Three students from those classes have gone on to study architecture.

Construction

The exchange of ideas continued during construction, with AFH engaging a local artist to design selected pieces of the project. The most visible example is the guardrail system along the edge of the mezzanine gallery, which incorporates junked automobile windshields, a concept that arose out of a desire to reuse materials. The architects worked with the artist and the local building inspector to assure that the resulting system would meet required safety standards. Other elements designed by the artist include custom-made stainless steel sinks incorporating scrap material from the building skin and exterior railing supports made from abandoned train tracks that were removed from the street during utility work for the project. The artist is now teaching a sculpture studio at AFH.

Operations/Maintenance

The building was designed for ease of maintenance with simple interior and exterior finishes requiring little upkeep. Mechanical systems can be adjusted manually or automatically. The photovoltaic panels were angled to promote self cleaning by rainwater.

Commissioning

AFH contracted for both prerequisite and additional commissioning for LEED credit.

Post-Occupancy

Continuous monitoring of the building systems, including onsite electricity production and electricity and gas use, began as soon as the building was occupied. Initial photovoltaic system tests showed all panels to be operational and output to be within the design goals.

In the spirit of promoting awareness of environmental issues, the finished building provides opportunities for teaching the concepts of conservation and sustainability. A small “truth window" into the exterior wall provides a view of the components of the wall system and the extra insulation. A glass pipe incorporated into the roof drainage system and visible in the main gallery promotes awareness of the need for efficient water use by reminding the occupants that the only water used for landscape irrigation is rainwater harvested from the roof. AFH also has plans for an environmental education program, Spiritus Solaris, that will involve students in monitoring the production, collection, and use of water and energy within the building.

Additional Images

Project Team and Contact Information

| Role on Team | First Name | Last Name | Company | Location |

|---|---|---|---|---|

| Owner/developer | Susan | Rodgerson | Artists for Humanity, Inc. | Boston, MA |

| Architect | Patricia | Cornelison, AIA, LEED AP | Arrowstreet, Inc. | Somerville, MA |

| Architect | Anthony | Iacovino, AIA, LEED AP | Arrowstreet, Inc. | Somerville, MA |

| Environmental building consultant | Mark | Kelley, P.E. | Building Science Engineering | Harvard, MA |

| Artist | Nick | Rodrigues | Boston, MA | |

| Structural engineer | Rene | Mugnier, P.E | Rene Mugnier Associates, Inc. | Cambridge, MA |

| Civil engineer | Steve | Garvin | Samiotes Consultants, Inc. | Framingham, MA |

| Commissioning agent | Mark | Warren, LEED AP | SEI Companies | Boston, MA |

| Contractor | David | Marceau | T.R. White Company, Inc. | Boston, MA |

| Lighting designer | Addison | Kelly | US Lighting Consultants | New York, NY |

| Mechanical engineer | Mohammed | Zade | Zade Company, Inc. | Boston, MA |

| Code consultant | Robert | Carasitti, P.E. | Schirner Engineering | Framingham, MA |

| Geotechnical engineer | Kevin | Martin, P.E. | UTS of Massachusetts, Inc. | Stoneham, MA |

| Specifications consultant | Jack | Fogg | Whitinsville, MA |