Austin Resource Center for the Homeless

Project Overview

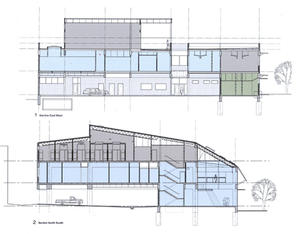

Much more than an emergency shelter, the Resource Center serves as a meeting place and support center, helping people transition out of homelessness through its many programs. The building includes a large common-use room, showers and locker rooms, laundry facilities, a computer room, an art studio, and offices for various community-support agencies. A clinic, located on the first floor, provides health services. The second floor houses a large commercial kitchen and dining room. Located on the third floor in a pavilion-like structure on the roof is the 100-bed overnight shelter. The sleeping area's rooftop terrace opens up to panoramic views of the city.

Design & Innovation

Predesign

The project owner, the City of Austin, required that all new City of Austin projects be certified through the U.S. Green Building Council's LEED(r) Rating System. The Resource Center rating, expected to be Silver, is pending.

Design

Design-team meetings, including the owner and the sustainability consultant, were held on a weekly basis, and stakeholder meetings with representative of the downtown community were held at regular intervals.

Potential LEED points were tracked throughout the design process.

Computer modeling guided the placement of solar shading.

Construction

The commissioning agent and sustainability consultant attended weekly construction meetings. A portion of each of these jobsite meetings was allocated to LEED and other sustainability issues.

The commissioning agent wrote field reports pertaining to indoor air quality issues.

The Resource Center is sited on a former brownfield in downtown Austin, within easy access of several bus lines. The project also includes preferred parking for carpools, storage space for bicycles, and a fueling station for an electric car.

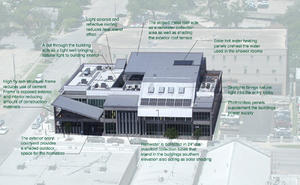

A 13,000-gallon rainwater collection system supplements the building's water supply. A passive-solar hot-water system preheats water for the showers, and a photovoltaic array supplements electricity usage.

The "stack-cast tilt-frame" structural system reduced the amount of finished materials and formwork used on the building and increases the quality of the exposed concrete finish. Flyash was used to replace 45% of the cement in the concrete. Concrete and other structural materials were left exposed in much of the building. Many of the materials used in the project contain rapidly renewable or recycled content. The project also includes FSC-certified wood and a range of locally manufactured materials. Polyvinyl chloride (PVC) products were avoided.

The strong connection between the interior and exterior, created through the numerous interpenetrating volumes, allows natural light and views into more than 90% of the work spaces. About 10% of the space can be naturally ventilated. Materials with low emissions of volatile organic compounds also contribute to a healthy environment.

Regional/Community Design

The site was selected for its proximity to Austin's downtown homeless population. It was certified as a brownfield by the U.S. Department of Environmental Protection and required extensive remediation.

To encourage alternative transportation, the Center includes parking space for bicycles and changing facilities for bicycle and pedestrian commuters. The project also includes a fueling station for an electric vehicle and preferred parking for carpools and vanpools. Only limited parking is available for single-passenger vehicles. The Resource Center is within 1/4 mile of six different bus lines.

Community connection

The Resource Center connects to the city through its open, accessible spaces. Located on a corner in Austin's downtown, the building opens to the street through its corner entry courtyard and two-story lobby. Large windows allow passersby to see the activities occurring inside. A shaded exterior courtyard connects with the homeless people living on the street.

The building reflects an attitude of outreach, openness, accessibility, and respect for the homeless. The mixed-use program is open and accessible to the homeless population in the neighborhood. The creation of a homeless resource center and shelter in the downtown has had a far-reaching, positive impact on the social fabric of the city.

Land Use & Site Ecology

The building is sited on an existing 1/4 block in downtown Austin. The basic site organization makes use of an existing alley for service and vehicular entry, continuing the existing pattern of development in the downtown area.

Only native and adapted plants were used to landscape the site.

Bioclimatic Design

The project has a reflective roof coating (75% reflectivity and 0.91 emissivity), lowering interior cooling loads and reducing the project's contribution to the urban heat-island effect.

Light trespass into the night sky and adjacent private property was minimized through the use of diffuse exterior light and low exterior lighting levels.

Light & Air

Interpenetrating volumes and combination of interior and exterior space allow for abundant natural light; more than 90% of the total building is daylit and has direct views to the outside.

The building was designed to comply with ASHRAE Standard 62 for ventilation levels and Standard 129 for ventilation effectiveness. Interior carbon dioxide levels are monitored, and ventilation is increased when necessary. Outdoor roof terraces allow for natural ventilation, and 10% of the building can be ventilated or cooled by opening the doors.

Paints, sealants, coatings, adhesives, engineered wood products, and carpets were selected for their low emissions of volatile organic compounds (VOCs).

Permanent dust and dirt mats at the entry doors collect moisture, dirt, and other pollutants as people enter the building. The Resource Center staff have implemented a green housekeeping plan, relying on less toxic cleaning products, and janitor closets have dedicated exhaust systems to ensure that chemical fumes do not enter the main building interior.

The project team implemented an indoor-air-quality management plan during construction, including a two-week flush-out period prior to occupancy, and an operational plan to monitor indoor air quality is being developed.

Metrics

Water Cycle

A 13,000-gallon rainwater-collection system reduces runoff from the site. Water from this system is used for all of the irrigation and as an alternate supply for flushing toilets and urinals. Using rainwater for flushing reduces the building's wastewater generation by more than 50%.

Infrared sensors on the building's faucets limit water use, contributing to a 30% reduction in indoor potable water use. This translates into approximately 600,000 gallons of water saved each year.

Energy Flows & Energy Future

The Austin Resource Center for the Homeless is expected to use 20% less energy than a conventional building.

The building includes extensive daylight harvesting. Deep structural frames allow sunlight to enter the building during the winter, but not during the summer. The central light well, which is oriented along a north-south axis, allows a small portion of direct sunlight to enter the building while the majority is reflected from the metal-panel cladding glazing inside the light well. The third-floor roof terrace extends over a portion of the western flat roof, shading part of the roof area. The building's exposed concrete frame elements act as thermal mass, remaining cool during the early portion of the day and radiating heat in the evening.

The project uses SEER-12 rooftop air-conditioning units. The refrigeration for the main building systems is free of both CFCs and HCFCs, reducing the potential to deplete the Earth's ozone layer.

The building includes 48 donated photovoltaic panels, which generate 0.43% of the building's electricity use. Solar hot-water panels preheat water for uses in the building.

Motion-sensor lighting controls exceed the requirements of the Texas energy code (SB5) and ASHRAE 90.1-1999.

All of the grid-supplied energy used by the Center comes from renewable sources.

Metrics

Materials & Construction

The "stack-cast tilt-frame" system, developed specifically for this project, reduced the amount of finished materials and formwork used in the building and increased the quality of the exposed concrete finish. Flyash, a byproduct of industrial processes, was used to replace 45% of the portland cement in the concrete. By replacing cement, which is energy intensive to produce, flyash reduces the amount of greenhouse gases released into the atmosphere.

Where possible, the design relied on base materials and omitted the use of finished materials. Concrete flooring and structural and mechanical systems were left exposed in much of the building.

More than 20% of the building materials, by cost, were manufactured within 500 miles of the project site. Of these, 50% were also extracted or harvested within 500 miles. The glazed brick comes from a locally owned, family-run business, the compressed straw panel was produced locally and the exterior metal panel was produced in Houston.

FSC-certified wood was specified for blocking and casework. Compressed straw panels were used for the ceiling. Along with concrete, linoleum and carpet tile were used as flooring materials. Recycled-content materials were preferred. Polyvinyl chloride (PVC) products were avoided where possible.

Recycled glass cullet was used in the planting area sub-base. A nontoxic, stainless-steel termite barrier was used around the building. Organic fertilizer and mixed organic compost were used for landscaping, and an integrated pest management plan allows only pesticides that have been approved by the Public Health Authority.

Smoking is prohibited inside the building.

Diversion of Construction & Demolition Waste

More than 50% of the construction waste, by weight, was recycled.

Long Life, Loose Fit

The second-floor office area was designed as an alternative to individual offices. The program called for 17 individual offices; however, since many of the offices were to be used only one day a week, an open office area with a range of cubicle sizes (from small work carols to larger 8’x8’ cubicles) was provided. Three shared meeting rooms allow workers to hold private meetings. This arrangement allows for greater flexibility while taking up less space.

The large second-floor rooms (the cafeteria and multipurpose or conference rooms), were grouped together to allow use as a sleeping area, and the third-floor roof terrace allows for possible expansion and additional sleeping space.

The building's exposed materials, including the concrete frame elements, exterior glazed brick, and interior steel detailing, are extremely durable. The white glazed brick, metal panel, and perforated metal, although very durable, add a lightness and delicate quality to the building finishes.

Other Information

Finance & Cost

Funding was made available for this project through a loan to the City of Austin from the U.S. Department of Housing and Urban Development.

Financing Mechanisms

-Loans: Public institution

Cost Data

Cost data in U.S. dollars as of date of completion.

-Hard cost: $187 per sq foot ($2,010 per sq meter)

The total construction cost was about $5 million. The total project cost — including land acquisition, design fees, and all other soft costs, in addition to the construction cost — was about $8 million.

Sustainable design and construction practices have many broad-reaching and complex variables. The interrelated aspects of this design affected the trades in different ways. The relationships between the structural system, forms, and spatial organization are very tight. The building design could have benefited from the mechanical system being designed with a similarly integrated design approach.

This project was publicly bid. The winning contractor, the low bidder, was new to sustainable building practices. Although the contractor did an excellent job, the process of ensuring that certain materials or methods were used was difficult to track due to the complexity of the building. The public bid process does not allow for the involvement of the contractor in the design phase or construction document phase of work.

Additional Images

Project Team and Contact Information

| Role on Team | First Name | Last Name | Company | Location |

|---|---|---|---|---|

| Architect (Specifications) | Val | Fuger | LZT Architects, Inc. | Austin, TX |

| Owner/developer | Cynthia | De Witt Jordan | City of Austin Public Works Department | Austin, TX |

| Owner/developer | Mary | Rychlik | Austin/Travis County Health and Human Services Department | Austin, TX |

| Contractor | Sam | Kumar | Journeyman Construction, L.P. | Austin, TX |

| Environmental building consultant | Gail | Vittori | Center for Maximum Potential Building Systems | Austin, TX |

| Civil engineer | June | Routh | Urban Design Group | Austin, TX |

| Structural engineer | David | Powell | P.E. Structural Consultants, Inc. | Austin, TX |

| MEP engineer | Ali | Khataw | Encotech Engineering Consultants, Inc. | Austin, TX |

| Landscape architect | Diane | Steinbrueck | Winterowd Associates, Inc. | Austin, TX |

| Roofing consultant | Brian | Gardner | Austech Roof Consultants, Inc. | Austin, TX |

| Commissioning agent | Ricardo Troncosco | Troncosco | ACR Engineering, Inc. | Austin, TX |

| Interior designer | Bethany | Ramey Trombley | Austin, TX |