Greyston Bakery

Project Overview

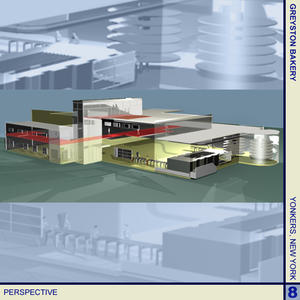

Built on a 1.6-acre brownfield site in Yonkers, New York, the Greyston Bakery is a state-of-the-art production bakery. This project is the intended catalyst to revitalize this blighted area. The new bakery is a continuous, automated machine to produce brownies and other baked products. Incoming sugar, flour, and cocoa are pumped to silos from an over-the-road tanker. From the silos, the ingredients are pumped to automated mixers, and a batter is created, formed, and then baked in a 40-foot-long tunnel oven. After the bake, two continuous spirals gradually cool the product, which is finally packaged and shipped.

Design & Innovation

The skin, mass, and orientation of the building are significantly impacted by passive energy design. The bakery is "form following function," modified by environmental constraints. The light shaft atrium was utilized as a design element to zone the building, creating separation from diverse functions while emphasizing circulation routes.

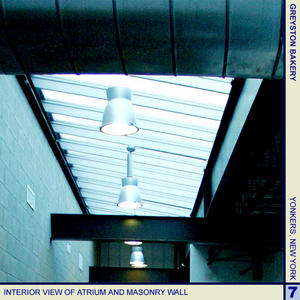

Natural light is introduced into the facility via a skylight atrium, a three-story light shaft, and numerous windows. The south-facing light shaft allows light from the roof to penetrate the interior spaces of the bakery. The atrium introduces diffuse natural light into the two-story office area, guaranteeing most employees natural light. Large clearstory windows and viewing windows are strategically located to both add light and allow views into the facility from the street. 50% of the building relies on natural light for some portion of the illumination.

The light shaft and atrium are also ventilated, allowing for natural airflow through the bakery, which eliminates excess heat from the ovens in the summer and supplements the primary ventilation system. The passive ventilation within the bakery is supplemented by a mechanical fresh-air make-up system that filters 99% of particulates from the air. Baked products are partially cooled by ambient outside air.

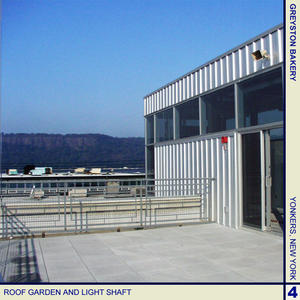

A roof garden serves as a public meeting place, and adds insulation to the roof.

An efficient impingement tunnel oven is used to bake the products. The oven is so well insulated that it does not feel hot to the touch.

Regional/Community Design

The single most important criteria in the development of the Bakery was the connection of the Bakery to the local community. The Bakery is the economic engine that feeds the Greyston Foundation and is the focal point of the Greyston objective to assist the poor and unemployable. To that extent, the bakery is located adjacent to the downtown area where most employees can walk to work or use mass transit – there is a bus stop at the site. Due to the economics, many of the employees use mass transit or walk to the facility.

The bakery is the focal point for the community. Many of the people who work at the Bakery are poor and considered unemployable individuals who are given a chance to be productive members of society. Due to their unfortunate financial conditions, many have no place to go after work. The bakery is more than a work place; it is their “living room.” A break room in the Bakery opens out to the reflecting pool. This room is a cafeteria, meeting room, and living room for the employees.

The building integrates itself with the community and is designed to allow the community to see the baking process. Large windows provide the community views of the internal functions of the baking process. A public-access mezzanine and meeting room allow the public to view the entire baking process, from incoming raw ingredients to finished brownies being packaged.

Land Use & Site Ecology

The site of the New Greyston Bakery is a brownfield property located along the Hudson River in a depressed and underdeveloped section of Yonkers which is presently being revitalized. Greyston specifically selected this site because the Greyston Foundation recognized that the development and clean-up of this site would be a catalyst to the revitalization of the Yonkers waterfront and industrial section.

The site of the Bakery is a brownfield property contaminated through years of industrial waste and pollution. As part of the development agreement with the NY State DEC, the entire site had to be capped to eliminate the migration of the existing subterranean pollution into the water table and ultimately the Hudson River. The mechanical systems and components were designed to run overhead instead of underground. Designing the system and components this way reduced soil disruption by an estimated 30%.

Grass-covered undulating earth berms and landscaping lend a natural look to the site. This natural top surface and its topsoil are separated from the brownfield site by a subsurface geotechnical layer. An exterior meditating, or reflecting, pool, intended to aerate the stormwater before it is washed into the storm system, is the focal point of the employee break room.

The building is oriented so that the two-story light shaft faces south, allowing natural light into the interior of the Bakery.

Bioclimatic Design

Orienting the light shaft to face south and orienting the atrium on a north-south axis allows the balcony to be passively heated and daylit. Concrete floors and concrete-block walls were utilized as heat sinks. Open steel-grate flooring was utilized to allow air and light infiltration into the depths of the bakery.

A roof garden was implemented over the bakery. Massive paving stones and planting were utilized to create additional insulation on the roof. The roof garden also services as a public meeting place that offers unobstructed views of the Hudson River and the panoramic New Jersey Palisades.

Light & Air

Natural light is introduced into the facility via a skylight atrium, a three-story light shaft, and numerous windows. The south-facing light shaft allows light from the roof to penetrate through steel grate floors into the interior spaces of the bakery. The atrium introduces diffuse natural light into the two-story office area, guaranteeing most employees natural light. Large clearstory windows and viewing windows are strategically located both to bring in light and to allow views into the facility from the street. 50% of the building relies on natural light for some portion of its illumination.

The light shaft and atrium are also ventilated, allowing for natural airflow through the bakery. This natural airflow eliminates excess heat from the ovens in the summer and supplements the primary ventilation system. The passive ventilation within the bakery is supplemented by a mechanical fresh-air make-up system that filters 99% of particulates from the air.

Water Cycle

The facility was designed to minimize water consumption. A cold-water wash-down and sanitation system was designed. Biodegradable chemicals are used for cleaning, along with tempered 120ºF water, rather than the standard 140ºF water. Most of the cleaning is accomplished using a vacuum system and compressed air. The vacuum cleans the Bakery and significantly reduces the amount of water required for wash-down and the sanitizing of the facility.

The plumbing system was designed to allow for the future installation of greywater non-potable uses, such as landscape irrigation and flushing toilets.

All refrigeration is air cooled rather than water cooled. The air is used to remove heat from the compressors rather than relying on water for heat exchange.

Energy Flows & Energy Future

Design for passive energy is a significant part of the Bakery's base design. A two-story atrium separates the offices from the bakery. A concrete block wall on the east side of the atrium serves as a heat sink, creating a greenhouse effect which helps to heat the office spaces. The atrium is ventilated to evacuate hot air in the summer months. A three-level light shaft, which bisects the Bakery, allows natural light into the interior of the bakery, reducing the need for artificial light. The light shaft also allows ventilation, helping to eliminate any excess heat created by the ovens during the baking process.

Efficient metal-halide lamps were used throughout the Bakery, reducing the energy required to light spaces. Numerous exterior windows were also strategically located to further allow natural light into the interior of the Bakery. The natural light has an additional benefit of controlling the infestation of vermin and reducing the necessity to rely on chemicals and traps to control pests.

The high-efficiency impingement tunnel oven uses considerably less (gas) energy to bake the product. Fans are used to evenly distribute the heat generated by the burners, insuring uniform temperate and, ultimately, requiring less energy to bake the brownies and exhausting less heat through the flues. The oven is so well insulated that the exterior does not feel hot to the touch.

After the brownies are baked, they are cooled prior to cutting and packaging. A two-stage, conveyorized, spiral cooling system was employed to reduce the energy needed to cool the baked products. The first stage uses ambient outside air, significantly reducing the energy required to cool the product.

Energy Security

Strategies to reduce peak electrical demand include controlling the freezer so that its temperature drops during times of low electric demand, such as nighttime, and is allowed to rise during times of peak electric demand, during the daytime.

The building is designed to accommodate an energy management system to monitor temperature and lighting. The management system is designed to regulate controls and to monitor performance, thereby insuring the optimum utilization of the systems.

Metrics

Materials & Construction

The building's exterior skin is an insulated galvanized metal panel, which reflects light and heat while creating an excellent insulation system. A concrete-block wall in the atrium creates a distinct aesthetic contrast separating the office area from the bakery. The mass of this wall also serves as a heat sink, helping to heat the atrium and the offices. Extensive thermo-pane glazing in thermally broken aluminum frames allows light into the facility. Concrete floors are also used throughout.

Recycled products were utilized where possible. The countertops in the office are made of recycled wheat, and the countertops in the employee break room are made of recycled glass. The structure is made of prefabricated steel members.

Long Life, Loose Fit

The facility was designed utilizing prefabricated long-span steel framing. The columns are primarily at the exterior walls and are far apart, allowing for unlimited retrofit potential. No bearing partitions constrain future development or retrofit. The basic infrastructure and design could accommodate uses including office, manufacturing, commercial, and municipal uses.

Other Information

The owner was able to obtain several different public grants to offset the construction costs. These included federal, state, and city funds, which were used to remediate the polluted property and implement the passive energy design.

In addition, the project cost was substantially reduced through value engineering and alternative construction methods, which achieved the required goal at a reduced cost. For example, substituting a pre-engineered building for conventional steel framing reduced the superstructure costs by 20%.

Financing Mechanisms

-Grant: Public agency

Cost Data

Cost data in U.S. dollars as of date of completion.

-Total project cost (land excluded): $9,000,000

The owner is anticipating a 7-year payback in energy savings to offset the initial cost of green systems. The cost of the light shaft and fenestration system was approximately $40,000, which would be amortized by the elimination of required lighting and ventilation.

The lesson we learned from this project is don't try to accomplish all of your design objectives in one building. Trying to satisfy the brownfield issues while designing a green building that is economically feasible, creating a state-of-the-art automated bakery, and establishing an icon for the community forced unwanted compromises and project delays.

The client must accept the concept that a “green building” has added value. The client must also acknowledge that the construction of their facility has an impact on the environment and can be a positive catalyst for change. The client must be committed to a “green building” ideal and be willing to pay additional money for a green building.

Additional Images

Project Team and Contact Information

| Role on Team | First Name | Last Name | Company | Location |

|---|---|---|---|---|

| Architect | David | Cybul, AIA | Cybul and Cybul Architects | Edgewater, NJ |

| Architect | Martin | Cybul, AIA | Cybul and Cybul Architects | Edgewater, NJ |

| Architect | Oliver | Wilhelm, AIA | Cybul and Cybul Architects | Edgewater, NJ |

| Electrical engineer | Patrick | Boccio | Clive Samuels & Associates, Inc | Princeton, NJ |