San Mateo County Sheriff's Forensic Laboratory & Coroner's Office (San Mateo County Forensics Lab)

Project Overview

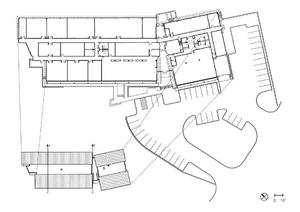

The San Mateo County Forensic Laboratory and Coroner's Office is a highly secure and technologically innovative laboratory facility designed to provide a superior workplace, flexibility to accommodate changing needs, and advanced resource efficiency. The facility houses eight distinct forensic laboratories and the coroner's office.

Design & Innovation

Sustainable design was identified as a project goal early in the design process. Sustainable design goals were developed based on the LEED green building rating system; however, the decision to certify the building with the U.S. Green Building Council was not made until the project design was nearly complete. As the project progressed, it became evident that the decisions made in the interest of meeting the program requirements yielded a design that could be certified at the Silver level. Based on the positive outcome of this project, the county has passed a resolution requiring LEED certification for all new facilities.

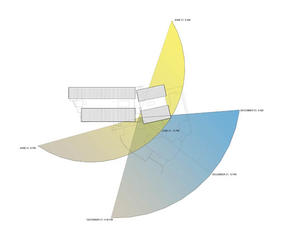

The design was developed using an integrated multi-disciplinary design process. Basic design decisions regarding building orientation and massing were based on passive solar design principals, and energy analysis was used to optimize the design.

Regional/Community Design

The project is sited adjacent to a major highway and several arterial streets served by three bus lines within 1/4 mile of the project. This particular site was selected in a site evaluation process to centrally locate this facility within the county, reducing travel distances for customers and employees and providing better service to the community.

The project provides 46 parking spaces, substantially fewer than the 96 spaces encouraged by the parking ratio utilized in the adjacent community. Car-pool spaces, as well as bicycle racks and showers encourage alternative means of transportation.

As this is considered a secure facility, no accommodations were made for public spaces on the site.

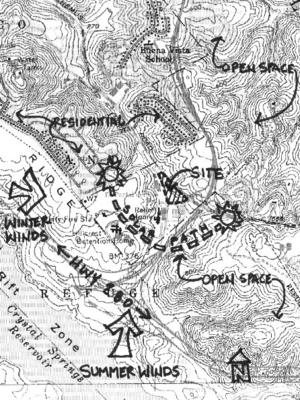

Land Use & Site Ecology

The facility is located in San Mateo, which is in San Mateo County, about 30 miles south of San Francisco. The climate is mild with cool temperatures throughout much of the year. Energy costs are high and the value of peak-load reduction is well understood. This climate supports use of natural cooling systems and the high portion of daylight hours boosts the efficiency of photovoltaic systems. The facility design reduces energy requirements by over 50% relative to California's stringent Title 24 energy code and reduces peak loads by over 50% as well.

Bioclimatic Design

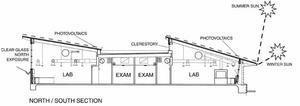

This facility provides a bright, open, and airy work environment while meeting stringent security requirements. All regularly occupied areas of the building are daylit, and office areas have operable windows. The orientation of the building, large roof overhangs, north-facing clerestory windows, and canted windows on the southwest reduce glare while maximizing daylight. Energy demand has been reduced over 50% relative to the stringent California Title 24 energy requirements, and renewable energy systems supply all non-HVAC energy requirements. The building also incorporates green building materials and an aggressive recycling plan diverted over 78% of construction waste from landfills. This project demonstrates that integrated, high-performance design can produce a better workplace while substantially reducing operating costs and significantly reducing reliance on the electricity grid.

Light & Air

This facility provides a bright, open, and airy work environment while meeting stringent security requirements. All regularly occupied areas of the building are daylit, and office areas have operable windows. VAV boxes for the office spaces are interlocked with the windows to shut down when a window is opened.

The orientation of the building, large roof overhangs, and canted windows on the southwest reduce glare while maximizing daylight. Office areas have floor-to-ceiling canted glazing, with fritted glass on the lower portion to diffuse low-angle sun that is not controlled by the deep architectural overhang. Users in both the lab and the office portions of the building have the ability to control lighting levels for their individual work areas from their desktop computers.

Entry of Pollutants

-Keep positive pressure in the building

-Avoid carpet and other hard-to-clean floor surfaces near entry

Thermal Comfort

-Maintain relative humidity levels between 30% and 60%

-Provide occupants with the means to control temperature in their area

Visual Comfort and The Building Envelope

-Use skylights and/or clerestories for daylighting

Visual Comfort and Interior Design

-Place primarily unoccupied spaces away from daylight sources

Direct Exhaust from High-source Locations

-Ensure that lab hoods exhaust to the outdoors

Reduction of Indoor Pollutants

-Use only very low or no-VOC paints

Pollutant Management During Construction

-Minimize exposure of textiles and uncoated paper to high VOC concentrations

Ventilation During Construction

-Purge the building of VOCs during furniture installation prior to move-in

Water Cycle

The region experiences distinct dry and rainy seasons, generally experiencing no rainfall between May and October each year. Due to the long dry season, water efficiency strategies have a particularly high value. The landscape design relies on native grasses and wildflowers for the majority of the site area. These provide a beautiful backdrop for the facility, and will require irrigation only until established. Landscaped areas around the parking lot and building entry consist of trees, shrubs, and groundcover that are irrigated with water-efficient bubblers and localized sprayers. However, irrigated landscape area accounts for less than 10% of the overall landscaped portion of the site. A natural drainage course with native willows was not disturbed by the construction. Permeable paving and bioswales were considered but not implemented because of the highly clayish soils and the steep slope.

Waterless urinals, ultra-low-flow shower heads, and low-flow toilets were included in the building to reduce the domestic water use by over 40%.

Energy Flows & Energy Future

To reduce energy loads, the facility uses passive-solar design strategies including: a high performance envelope, building orientation with long facades along the north-south axis, integrated daylighting, architectural sun control, and lighting controls.

Laboratory facilities are highly energy intensive buildings due to the need to provide one-pass air systems and high air-change rates to protect building occupants from hazardous chemical exposure. This facility reduces total energy usage through building-related load reduction strategies, integrated daylighting, state-of-the-art VAV laboratory equipment, and efficient HVAC systems. Operable windows in office areas are interlocked with the HVAC system to eliminate air conditioning losses while windows are open. Energy use is 50% less than the stringent California Title 24 energy requirements allow, and renewable-energy systems supply approximately 30% of the annual energy requirements.

The photovoltaic roof has a peak output of 170 kW, and is expected to produce 283,000 kWh per year, resulting in $44,000 in energy cost savings (the County has a flat electrical rate, so no demand charges apply). During off-peak daylight hours, this facility exports energy back to the power grid.

Metrics

Materials & Construction

Materials were selected to be durable and low-maintenance and to minimize lifecycle impacts. The specification identified standards for environmentally preferable products including local materials, renewable materials, recycled content, low VOC potential, avoidance of toxic materials, and wood certification.

Exterior materials include concrete block, metal panel standing seam roofing with photovoltaic panels, and glazing. Interior materials include linoleum, bamboo, ceramic tile, sealed concrete, carpeting in office areas only, drywall with zero-VOC paint, FSC-certified wood, and wheatboard casework.

Diversion of Construction & Demolition Waste

A comprehensive construction waste recycling program diverted over 78% of all construction waste from landfills.

Design for Materials Use Reduction

-Enhance existing features in landscaping

-Group or stack bathrooms and other water-using spaces

-Consider exposing structural materials as finished surfaces

Recyclable Materials

-Select products that manufacturers will take back for recycling

Job Site Recycling

-Seek a waste hauler who can separate recyclables out of commingled waste

-Require that subcontractors keep their wastes separate

Pre-Consumer Recycled Materials

-Specify aluminum products made from high levels of recycled scrap

-Use concrete masonry units with recycled or industrial-waste aggregates

Materials and Wildlife Habitat

-Specify bamboo flooring instead of hardwood

-Use wood products from independently certified, well-managed forests for finish carpentry

Long Life, Loose Fit

The project was designed to extend the useful life of the facility through design flexibility and the use of durable and low-maintenance materials, structure, and building systems. Flexibility is designed into the building to accommodate changes in program requirements and to provide room for internal expansion through conversion of office space into additional laboratory space. Several office areas were prepared for utilities for laboratory expansion so that the owner will not outgrow the facility. Laboratories were designed as flexible modules with a substantial amount of moveable furniture to maximize adaptability as needs change. Ceilings were eliminated from most lab areas of the project, and a two-way strut grid was provided to accommodate existing and future utilities so that systems can be upgraded and augmented with ease.

Other Information

Financing Mechanisms

Equity: Government appropriation

Building and interior fit-out costs for this facility are within the range of typical forensic laboratory costs; however, site development costs were higher than average due to the complication of building on a sloped site.

The 26,000 square feet of rooftop-mounted photovoltaic panels were cost-justified independently of the rest of the building construction cost. These panels, which will produce enough power to accommodate all non-HVAC electrical requirements, will provide energy cost savings estimated at about $70,000 per year. Rebates and incentives offset 30 to 40 percent of the initial cost required to build the system. Without considering energy cost escalation, the installation has a simple payback period of under 10 years.

This project confirmed to our team that green building strategies are appropriate even in the context of a highly secure and technologically complex building program. In fact, the sustainable design strategies will help the county to be more prepared in the case of an emergency as the building is daylit, office areas can be naturally ventilated, and photovoltaic systems will continue to function even if there is an electric power disruption.

Additional Images

Project Team and Contact Information

| Role on Team | First Name | Last Name | Company | Location |

|---|---|---|---|---|

| Architect (Project designer) | Alan | Bright | Hellmuth, Obata + Kassabaum | San Francisco, CA |

| Sustainable design | Sandy | Mendler | Hellmuth, Obata + Kassabaum | San Francisco, CA |

| Landscape architect | Kathy | Doi | Hellmuth, Obata + Kassabaum | San Francisco, CA |

| Mechanical engineer | Dick | Powers | Hellmuth, Obata + Kassabaum | San Francisco, CA |

| Interior designer | Archie | Stephens | Hellmuth, Obata + Kassabaum | San Francisco, CA |

| Civil engineer | Kurt | Wurnitsch | Brian Kangas Foulk | |

| Structural engineer | Patrick | Crosby | The Crosby Group | Redwood City, CA |

| Energy consultant | Greg | Cunningham | ESS Engineering | |

| Laboratory planner | Kenneth | De Boer | Earl Wall Associates | San Diego, CA |

| Design/builder (Project manager) | David | Burge | Turner Construction Company | Oakland, CA |