Federal Center South Building 1202

Project Overview

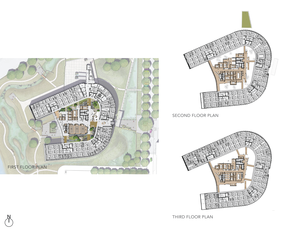

Federal Center South Building 1202 is the result of responding to both the 2009 American Recovery and Reinvestment Act (ARRA), which focused on improving our nation’s infrastructure and creating jobs, and the U.S. General Services Administration’s (GSA) Design Excellence program which was established to procure the nation’s best architects in order to achieve the most innovative and high performance design in federal government building projects. With reuse and high energy-performance as part of both the GSA and ARRA requirements, the new 1202 building transforms a 4.6-acre brownfield site into a highly flexible and sustainable 209,000-square-foot regional headquarters for the U.S. Army Corps of Engineers (USACE) Northwest District.

The project’s integrated design-build team developed a design and construction solution that fuses programmatic, functional, and aesthetic objectives while achieving a new standard for high-performance, cost-effective and sustainable workplace environments. The solution synthesizes the Design Excellence project standards, optimal performance, and community connectivity, all fundamental to environmentally responsive design and stewardship of the environment.

The project was delivered on time and within the original $65 million budget. The project team programmed, planned, and designed the project in under 18 weeks under a performance-based contract with 0.5% of the contract value being retained until confirmation of actual energy performance one year into occupancy. The entire project was planned, programmed, and built in less than two and a half years.

Design & Innovation

Driven by aggressive sustainable design and high-performance goals, the design integrates active and passive systems, materials, and strategies in new ways. Its optimized form, systems and building orientation will place Building 1202 within the top one percent of energy-efficient office buildings across the country. Current energy models predict the building to operate at a “net zero capable” EUI of 20.3 kBtu/ft2/year, performing 40 percent better than ASHRAE 2007. The building will earn an ENERGY STAR Score of 100 and comply with 2030 Challenge goals.

Going beyond GSA’s project requirement of LEED Gold certification, the project team has taken upon itself to attempt to achieve LEED Platinum and is currently tracking one point below Platinum. Every major aspect of the building is designed in direct response to creating a high performance building that establishes a new workplace standard.

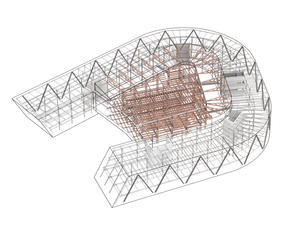

The project is one of the first in the region to use structural piles for geothermal heating and cooling, as well as a phase change thermal storage tank. Two new products, chilled sails and open office lighting, were developed and manufactured specifically for this project to help achieve aggressive energy targets. To optimize the use of the available reclaimed timbers, the team designed, tested, and constructed the first wood composite floor system in the United States.

Regional/Community Design

To meet Federal security and anti-terrorism requirements, the building is not accessible to the public. The Army Corps of Engineer’s former facility configuration did not meet their seismic, security or operational needs. GSA conducted an evaluation of alternatives, including the renovation of the Corps’ existing space and concluded that reinvesting in the site for the development of a high-performance workplace would meet the security and growth requirements more cost-effectively. In addition to creating a more sustainable workplace environment for the USACE, a key design goal was to create a flexible work environment offering a sense of place and community for the 700 employees who occupy the building.

The former brownfield site, in south Seattle’s transforming industrial area, is not yet a truly walkable or interactive neighborhood. However, as the first new building on the Federal Center South campus in many years, it celebrates USACE’s mission of transforming and restoring our nation’s waterways with an environmental focus. Building 1202 renews the campus while celebrating the adjacent, historic Albert-Kahn 1930 designed former Ford Motor Company building 1201. The new 1202 building signifies the resilience and future of the campus and the Corps, akin to the 1201 building, itself a recovery and sign of regeneration following the Great Depression.

Metrics

Land Use & Site Ecology

Located on the banks of the Duwamish Waterway—a superfund site—the ecology of the site and goal to return the riverbank to the USACE was of significant importance. The site’s industrial past and poor air quality, due to a nearby cement plant, were of chief consideration in the building design. While desirable, natural ventilation was not feasible because of particulates in the air and Department of Defense security requirements. To ensure a high level of indoor air quality, 100% filtered outdoor ventilation air is delivered underfloor.

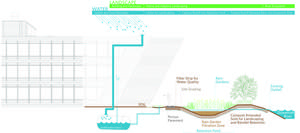

The project transforms 4.6 acres from 100 percent impervious to 50 percent pervious landscape. The initial design competition brief required that all storm water be pumped uphill from the site into the city’s municipal storm water system. The team presented an early concept to leverage the site’s natural ecology. On-site drainage runoff is treated within storm water surface ponds, raingardens, and wet ponds, and then infiltrated. 100% of the storm water will be collected around the perimeter of the site and directed to the western-most pond, thereby eliminating the need to connect to the already over-taxed city storm water system.

Central plant equipment was placed on the roof of the office building to preserve more landscaped open space to further reduce impervious area.

Bioclimatic Design

Intelligent Envelope

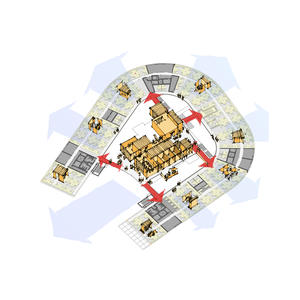

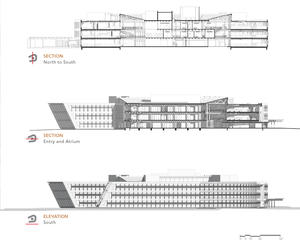

Early design studies were used to optimize orientation and massing for annual energy use, as well as to reduce peak loads and overall HVAC system sizing. As a result, the massing concept optimizes north and south orientations and created a central atrium opening to the west, thereby minimizing work spaces on the most troublesome side. The central atrium approach also provided cost savings and energy-efficiency benefits, allowing the various USACE departments to share conference room amenities, thus resulting in reduced square footage and permitting a different mechanical approach to these spaces from the regular office spaces.

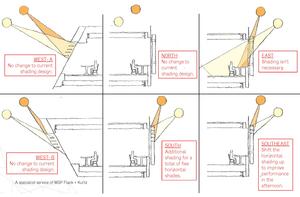

Solar Control

Exterior sun-shading elements, clerestory glazing, and internal adjustable window coverings control heat gain, glare and provide uninterrupted views to the outdoors. The ribbon system is designed with vertical blades across the entire perimeter and augmented with horizontal sunshades tuned to the orientation starting with zero on the north and transitioning to one, two and three as the facade transitions around the oxbow from east to south. Peak cooling loads are targeted for a 30% reduction in the perimeter zone, resulting in a 10% reduction in the central plant cooling capacity.

Renewables

The integrated design is developed to avoid the need for on-site renewable generation to meet the required energy goals. Initial life-cycle cost analysis of a solar domestic hot water system and supplemental photovoltaic system were outside the range of acceptable return. The roof is designed to allow the installation of a photovoltaic array in the future should the life cycle cost benefits improve.

Light & Air

Daylighting

The narrow 60-foot floor plate optimizes daylight penetration, reducing the need for artificial light and associated energy costs. Fifty-inch workstation partitions help maximize daylight effectiveness. The atrium experiences a variety of changing light experiences as the sun moves across the sky. A varying degree of frit across the glass roof responds to solar exposure, balancing light, views to the sky, and solar gain.

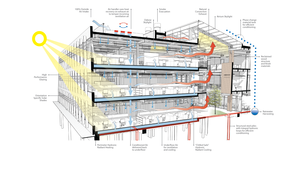

Indoor Air Quality

Natural ventilation was originally considered to save energy and promote occupants’ connection to the outdoors. Ultimately, this was not feasible because of federal security requirements and poor air quality stemming from the proximity of a cement plant. Instead, 100 percent outside air, MERV 15 filtered, flows into workspaces via under-floor plenums and then exits the building through the Atrium. Air handlers with heat exchangers at the top of the roof filter and temper incoming air from the exhaust air that rises naturally through the atrium. Air-testing was performed on-site to evaluate the need for a charcoal filtration system. Current air quality conditions don’t warrant the additional system, but space has been built in to accommodate a charcoal filtration system in the future as needed.

Metrics

Water Cycle

On-site drainage run-off is treated and infilitrated within storm water surface ponds, rain gardens and wet ponds. The runoff is collected around the perimeter of the site and directed to the western-most pond, mimicking natural site drainage patterns, and leveraging low-impact development techniques. The rainwater reuse system captures water from the roof and stores it in a 25,000-gallon cistern and treats it prior to being used for toilets, irrigation, a rooftop cooling tower and water features in the atrium. These systems will provide required water quality treatment. A series of exterior rain gardens were designed to drain and treat a 95th percentile rain event, entirely on-site eliminating the need for a connection to the city’s overtaxed storm water system.

An estimated 430,000 gallons of rainwater will be harvested annually—providing a 79 percent reduction in potable water use for toilet flushing and a reduction of irrigation demand by an additional 14 percent. In addition, potable domestic water use is reduced by 58 percent through efficient fixtures, low-water landscape and rainwater reuse.

Metrics

Energy Flows & Energy Future

Conventional building systems have been replaced with efficient hydronic heating and cooling. To enable these systems to perform at an optimal capacity within the project budget, an efficient building envelope—offering a high level of solar control and high performing glass, while transmitting ample daylight—reduces the magnitude of heating and cooling demand.

Energy and water introduced into the building are leveraged to their highest possible use. Conditioned air is delivered to the workspace via air handling units and exhausted passively through the atrium to a high-efficiency heat recovery system that preheats the new air as it enters the building.

Electric lighting design is a simple, repetitive task/ambient design that achieves a building-wide lighting power density of approximately 0.72 W/ft2 or lower.

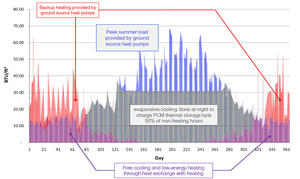

The design aims to capitalize on both daily and seasonal heat exchange patterns to collect thermal energy when available and store it for use when required. A thermal storage tank containing phase change material (PCM)—a solution that melts at 55°F, is used to absorb heat from chilled beams for use in morning warm-up the following day. Similarly a ground loop acts as a heat source for efficient heat pumps in winter when there is not enough heat collected from the chilled beams.

Metrics

Materials & Construction

As part of the project’s effort to reuse existing materials, the design-build team reclaimed approximately 200,000 board feet of structural timber and 100,000 board feet of decking from the decommissioned non-historic WWII warehouse on the site. Using a phased demolition process, wood components were individually harvested from the warehouse. The team pulled nails, unfastened bolts, removed brackets and devices, trimmed out fractures, and sorted the wood before it was shipped to a local mill for structural grading and fabrication for use in the new building. To optimize the use of the available size the engineer suggested the use of composite design for the floor system. Since this was the first time this type of design was used in the U.S., the team built a mock-up in the adjacent warehouse to test structural integrity of the proposed “composite timber/ concrete system.”

Construction waste is one of the most significant environmental impacts of the construction industry, with building activity in the United States generating about 40% of the total solid waste stream This project achieved a 99% diversion rate of construction waste.

Long Life, Loose Fit

As part of an integrated process, a base building model was developed to explore facade options and a number of technological opportunities. A robust building base maintains occupant comfort and is adaptable to programmatic changes without significant impact to energy performance.

The project is designed to meet GSA’s requirement for a building with a 50-year minimum lifespan, and mechanical equipment that lasts a minimum of 20 years. The campus site can also accommodate the 30-year expansion and redevelopment requirements for a number of other federal agencies.

The U-shaped form of the 1202 building is part of an integrated strategy that provides a flexible workplace footprint with minimal private offices. A new model for the Corps that promotes social equity, the open plan creates a healthy, productive, and collaborative environment for the 700 employees who occupy the building. The design provides the greatest flexibility and collaboration as well as the maximum building area enclosed within the minimal envelope.

The building program encourages interaction and innovation in keeping with the U.S. Army Corps of Engineer’s interdisciplinary work culture by providing centralized meeting spaces and kitchen amenities to be shared by all departments. Building 1202 provides long-term flexibility in a healthy, high-quality environment.

Collective Wisdom & Feedback Loops

The highly collaborative design-build project delivery method greatly contributed to the success of meeting, and surpassing, GSA’s performance requirements. As part of the one-year Measurement & Verification Plan to ensure energy-performance targets are met, a real-time dashboard system will provide instant feedback on energy use, helping to foster good environmental habits for the occupants.

Early integration of the representatives of the building owner/occupants, general contractor, architect, engineer and all sub-contracting parties made it possible for the team to work together to quickly detect and resolve potential challenges virtually through the use of building information modeling (BIM). This was especially important because all systems were exposed in the building’s design, thereby making the systems an integrated part of the architectural aesthetic.

During design, as contingency funds became available, the team worked with GSA to introduce betterments to achieve maximum value of the total budget. To improve life-cycle costs and energy-efficiency, betterments included: laminated glass with an integral metal mesh sunscreen to increase the performance of the extensive daylights; installation of geothermal piles; upgraded lighting control to provide dimmable ballasts at light fixtures and occupancy sensors at workstation task lights; and the rainwater harvesting system.

Other Information

The building was constructed for $270/ft2—a significant value for the high-performance environment, considering that typical new construction for office buildings in the Pacific Northwest costs approximately $450/ft2. Driven by the need to optimize schedule and budget, the design solution incorporates a number of strategies to maximize life-cycle, cost savings and value for every dollar of ARRA funding invested. These include:

Groundsource heat pump system: This hybrid system, in which the GHPS performs the majority of the heating and cooling throughout the year, but a chiller and boiler still exist to handle peak loads, saved $880,000 over the cost of a traditional well field.

Under-floor air distribution system provides easy, cost-effective plug-and-play layout reconfiguration options to respond to changing staffing and work structure needs.

The U-shaped building design and inclusion of a covered atrium maximizes the ratio of available floor plate square footage to external skin, minimizing energy loss and envelope costs.

Adoption of passive and active systems, including a phase change material tank and natural convection air return/exhaust and heat recovery system, reduce first energy costs and allow for reuse of naturally generated heat and cooling loads.

The project’s $65 million budget is on par with buildings of similar amenities, yet the real savings will be long-term because utilities costs will be low. It is set to consume one-third the energy of a comparably sized building. Studies indicate that the operating and employee costs of a building over a 25-year cycle are 90 percent of the costs, compared with the initial construction, which are about 10 percent.

To further enhance the building’s sustainable performance, the team developed, tested and evaluated betterments to the base design during the design and construction of the project so that the owner could incorporate betterments into the project as funding became available. Through this process the project team was able to add rainwater harvesting, a geothermal system, enhanced lighting controls, an energy dashboard, and improved glass in the main skylight.

The design/ build team has 0.5% of the original contract value at risk pending verification of the building’s energy performance after one-year of occupancy. This risk is shared between the contractor, architect, and the major subcontractors and design consultants who have primary responsibility for the building’s energy performance.

Additional Images

Project Team and Contact Information

| Role on Team | First Name | Last Name | Company | Location |

|---|---|---|---|---|

| Technical Architect/Project Manager | Todd | Stine | ZGF Architects LLP | Seattle, WA |

| Design Project Manager | Jack | Avery | Sellen Construction | Seattle, WA |

| Project Manager | Rick | Thomas | U.S. General Services Administration | Seattle, WA |

| Project Executive | Wilf | Wainhouse | Sellen Construction | Seattle, WA |

| Project Executive | Brad | Hayes | Sellen Construction | Seattle, WA |

| Construction Project Manager | Jim | Kesl | Sellen Construction Company | Seattle, WA |

| Superindendent | Rich | Olender | Sellen Construction | Seattle, WA |

| Partner, Project Executive | Robert | Zimmerman | ZGF Architects LLP | Seattle, WA |

| Principal, Designer | Dan | Simpson | ZGF Architects LLP | Seattle, WA |

| Structural Engineer | Jason | Black | KPFF Consulting Engineers | Seattle, WA |

| Civil Engineer | Mark | Veldee | KPFF Consulting Engineers | Seattle, WA |

| Mechanical Engineer | Tom | Marseille | WSP Flack + Kurtz / University Mechanical | Seattle, WA |

| High-performance Building Specialst | Andrew | Corney | Built Ecology | San Francisco, CA |

| Lighting Designer | Melanie | Taylor | WSP Flack + Kurtz | Seattle, WA |

| Telecommunications Manager | Herbert | Els | WSP Flack + Kurtz | San Francisco, CA |

| Electrical Contractor | Mahmood | Ghassemi | Lane Coburn & Associates, LLC / Sequoyah Electric, LLC | Seattle, WA |

| Landscape Architect | Mark | Brands | SiteWorkshop | Seattle, WA |

| Graphic Designer | Billy | Chen | StudioSC | Seattle, WA |

| Elevator Consultant | Steve | Mikkelsen | Lerch Bates | Seattle, WA |

| Acoustical Engineer | Julie | Wiebusch | The Greenbusch Group | Seattle, WA |

| Code Consultant | John | Gunderson | Rolf Jensen & Associates | Seattle, WA |

| Fire Protection Engineer | Eric | Tuazon | Tuazon Engineering | Seattle, WA |

| Geotechnical Engineer | David | Winter | Hart Crowser & Associates, Inc. | Seattle, WA |

Synthetically it brought a lot of dimensions together. It gathered the massing into a singular gesture which worked well on the site. It subjugates itself to a design idea about community. It had an intriguing structure of composite, concrete and timber, with each material, each component, working the best way that it can.

The contrast between a very sleek exterior and more of a warm interior was intriguing. It’s for the Army Corps Engineers and it feels like an appropriate home for them in that sense. It is muscular and humane at the same time. It’s really a beautiful work place.

It had a relatively modest budget compared to other commercial office buildings in the NW and for that to produce a building of this quality is quite commendable. It also had an interest in innovation. One was a phase-change material as part of their energy management system and another in a composite wood floor that they describe as being the first application in North America of that particular material. Just shows a sense of creativity and exploration and discovery which I think is of note.