Collaborative Life Sciences Building for OHSU, PSU & OSU

Project Overview

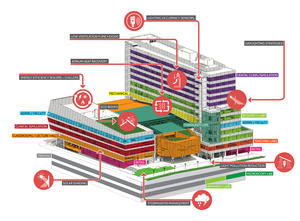

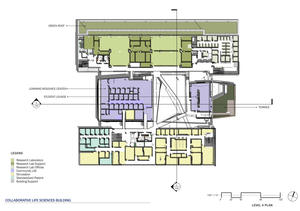

Oregon Health & Science University, Portland State University, and Oregon State University partnered to create the Collaborative Life Sciences Building (CLSB), a new allied health, academic and research building. CLSB provides academic classrooms, lecture halls, teaching laboratories, clinical skills and simulation laboratories, medical research laboratories, retail space, and two levels of underground parking. Also part of the project is OHSU’s Skourtes Tower, which houses the School of Dentistry. Together, they comprise 650,000 gross square feet of new construction in two wings – one 5-story and one 12-story – joined by a central atrium.

CLSB is the first building in OHSU’s new Schnitzer Campus at Portland’s South Waterfront. Located on a brownfield site constrained by adjacent roadway and bridge construction, the building is conceived as an innovative model of interdisciplinary health sciences education, research, and education. Interior glazed walls foster “research and teaching on display,” allowing occupants and pedestrians to view the activity in labs and classrooms. The atrium offers dynamic connections between program elements through connecting bridges and informal study areas for students. This complex project was delivered via Construction Manager at Risk delivery method in just 37 months through the use of an IPD-like team effort.

Design & Innovation

Early in the design process a decision was made to join the resources of three major universities to create a single building. Since each institution’s individually proposed spaces would not have been continuously occupied, the decision to share a single facility – versus each university creating its own – was arguably the greenest decision the project made. Today, the large 200 and 400-seat lecture halls are routinely scheduled for use from 7 a.m. to well into the evening: expensive laboratory teaching equipment gets triple use; and students have access to a single shared learning resource center.

As one of only two projects in the U.S. over a half-million square feet that has been certified Platinum under the LEED NC v2009 rating system, CLSB incorporates a number of sustainable design innovations. They include: transformation of an existing brownfield, light-pollution reduction, stormwater management, eco-roofs to reduce stormwater runoff, non-potable water for toilet flushing, atrium heat recovery, and low ventilation fume hoods. Innovative material re-use included salvaging oil drilling pipes for use as foundation piles, and repurposing existing site fencing. And by incorporating energy efficiency measures throughout, CLSB is predicted to save 45% more energy than a typical code building would.

Regional/Community Design

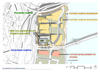

Having three institutions collaborate to deliver a single building helped to greatly increase efficiencies and reduce the environmental impacts inherent in new construction. CLSB’s connection to public transit and a web of bike and pedestrian trails significantly reduces parking demands and contributes positively to improved air quality.

Located halfway between both OHSU’s and PSU’s main campuses, this new campus is designed to be highly transit-oriented. The site is currently well-served by a streetcar line, bus lines, bike paths, a pedestrian path and the nearby aerial tram linking it to OHSU’s main campus. There are five transit stops within a quarter mile radius of campus, with two located immediately adjacent to building entrances. Beginning in the fall of 2015, the site will become a hub for light rail users when the city’s newest bridge and light rail line open service across the Willamette River – instantly linking CLSB to Portland’s east side.

Recognizing the building’s prominent location on a major bikeway, the building also provides bike locker rooms, showers, and 400 bike parking spaces – well beyond code minimum. It has a Bike Score of 91, a Transit Score of 78 and a Walk Score rating of 50.

Metrics

Land Use & Site Ecology

The project is located on a post-industrial, riverfront brownfield site that has been remediated, capped and prepared for re-development. As phase one of the OHSU Schnitzer Campus, these buildings set the standard for how the remaining brownfields in the vicinity can contribute to a vibrant, dense, revitalized hub of urban activity and education.

CLSB has a number of site design features that contribute to urban ecology, improved air and water quality. These features include 24,540 square feet of green roofs with additional integrated flow-through planters that absorb and treat rainfall run-off. The extensive green roofs and planters are vegetated with water-wise and drought-tolerant native plants. Additional native trees and shrubs planted along the east pedestrian spine of the project and on the west slope above SW Moody Avenue help to restore vegetation on the former brownfield. The fruiting trees, medium-sized and low shrubs provide a wide variety of food sources for wildlife throughout the season, along with cover and nesting opportunities. Creating this new wildlife habitat is particularly valuable given that the site lies only one block from the Willamette River. Additional stormwater captured from the roofs is used in a purple-pipe system for toilet flushing.

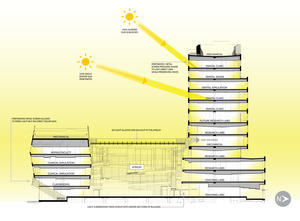

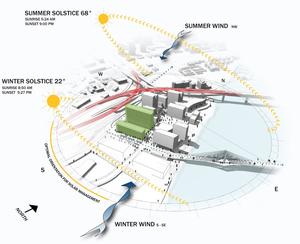

Bioclimatic Design

Although the zoning envelope dictated the building’s basic form – two towers joined by a central lecture-hall block – an analysis of solar resources, shading and wind patterns was performed to understand the microclimatic influences and evaluate the opportunities and challenges they present. For example, surrounding the relatively opaque central classroom block with a top-lit atrium allowed the classrooms to receive filtered daylighting instead of glare from direct sun. Creating thin tower masses and offsetting them maximized the daylight penetrating into the laboratories, dental operatories, offices and classrooms, while still allowing the central atrium to have an unobstructed view of the southern sky and direct access to reflected light.

Because CLSB is primarily an internally loaded building, the façade design focused on providing shading from solar gain. To understand the solar impacts, the team did detailed studies of multiple façade schemes. Each option was explored using shoe box modeling to determine the scheme’s likely energy performance and its impact on shading, access to views, potential for cross ventilation, and solar access. Ultimately, the team employed an innovative solution – a perforated metal sun screen attached directly to the window mullions – that minimizes the negative impacts, while keeping glazing desired for view and light.

Light & Air

The massing of CLSB’s towers was studied in relationship to the natural forces of sun, wind and light. Creating thin masses and offsetting them allowed us to maximize daylight penetrating into the laboratories, dental operatories, offices and classrooms, while still allowing the central atrium to have an unobstructed view of the southern sky and direct access to reflected light. Ceilings in the research labs were sloped in a butterfly configuration to further facilitate daylight penetration and reflection.

In addition to providing daylight and connecting the outdoors to the large lecture rooms, the atrium also serves as a collector of hot air as it rises in the space. By locating the mechanical floor level to the top of the atrium, heat recovery is easy and efficient. The atrium is also home to an amazing art piece, made of a series of LEDs of varying color temperature arranged in a sunburst pattern. Since daylight is so important to circadian health, it is very appropriate that this piece was selected for the main atrium space.

Attention to indoor air quality is demonstrated through increased ventilation, pollutant source control, and use of low-emitting materials.

Metrics

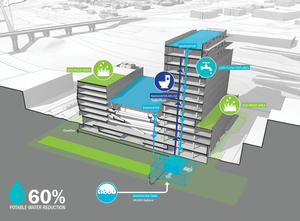

Water Cycle

Greater than 60% water savings is anticipated through a dual strategy of incorporating water-conserving plumbing fixtures with a rainwater reuse system. Low-flow fixtures and fittings are used throughout the building and result in a 35% water savings over a Code baseline building. By also incorporating a rainwater harvesting strategy, in the form of a 44,505-gallon underground tank, CLSB is able to capture 700,000 gallons of rain annually, which is reused to flush toilets in the north tower and central atrium. The south tower, which is primarily used for medical simulation, had water quality restrictions and was instead developed to ensure the minimization of storm water runoff via a green roof. This innovation minimizes the need to transport stormwater to wastewater treatment plants, saving offsite pumping energy.

The landscape was also designed with water conservation in mind. 16,500 square feet of the 27,000 square-foot landscape area is planted with non-irrigated native and adaptive species, which save water and provide habitat for local species. The remaining landscape incorporates minimal drip style irrigation.

Ultimately, the building is expected to save more than 1.5 million gallons of water annually – enough water to fill 17 Olympic-sized swimming pools.

Metrics

Energy Flows & Energy Future

CLSB is estimated to achieve a 45% energy use reduction compared to the LEED baseline. A number of design elements contribute to these savings, including high-performance lighting, daylighting and occupancy controls, low ventilation fume hoods, and an improved building envelope. The envelope boasts above-code insulation, high performance windows, a whole building air barrier and exterior shading strategies.

The building's enhanced mechanical systems also play a big role in energy savings. This system focuses on high indoor air quality and energy efficiency with an air recovery system in the atrium that captures heat and reuses it elsewhere in the building.

Much of the energy savings are a result of technologies that allow the building to be tuned based on actual use. One example is demand control ventilation sensors in the large lecture halls that automatically adjust fresh air levels based on room population. Another is low-ventilation fume hoods that automatically reduce fan speeds when the hoods are closed. Daylight and occupancy sensors on select luminaires provides an estimated 30% energy savings as does the incorporation of a task ambient lighting strategy in the research labs. CLSB received over $1,000,000 in incentive dollars, helping to offset first costs of the energy efficiency measures.

Metrics

Materials & Construction

As part of our design strategy, the team selected materials that are low-maintenance, durable, and low in VOCs. In many cases, the team was also able to choose products containing a high-recycled content, and products sourced regionally.

Helping reduce its environmental impact, CLSB’s use of recycled building materials topped an impressive 30%, based on cost. Additionally, building materials sourced regionally — within 500 miles of the site — accounted for 22% of all products in Divisions 3 to 12. These choices minimized the impacts of extracting and processing virgin materials, and helped reduce emissions associated with lengthy transportation.

During construction, the project diverted 85% of its construction waste away from landfills. That’s more than 1,000 tons of material recycled or reused instead of being landfilled. Not included in this waste diversion percentage is the reuse of old drilling rigs used as pipe piles in the foundation, which saved $3.3 million dollars in construction cost and prevented an additional 1,470 tons from ever entering a landfill.

Long Life, Loose Fit

CLSB is designed for an extended service life. The movement of major equipment through the building over time as components need to be changed out was taken into account with the design of the circulation systems and exterior facade. The complex program required a significant amount of research lab space, so the building’s structural system was designed to optimize lab bay spacing, allowing for both an efficient footprint and for the lab modules to fluctuate between different researchers over time. Generic lab layouts can be customized by individual researchers, promoting long-term flexibility and adaptability. An entire floor was built out as warm-shell space for future labs.

Materials throughout CLSB were kept simple and timeless to avoid the need for the regular “refreshing” of finishes. Concrete, glass, wood, and gypsum board are used in simple ways that when combined with the dynamic architecture create spaces that will stand the test of time.

The main mechanical floor of the building was centrally located mid-way up the north tower to minimize the size of building systems' runs. This decision also allows for the building’s innovative air handling units to double as a smoke evacuation system in the atrium.

Collective Wisdom & Feedback Loops

The City of Portland Design Review Commission and the local neighborhood association were engaged in the project design review on multiple occasions, with feedback being taken into consideration as the design evolved. Close collaboration between the project team and local jurisdictions was required due to concurrent infrastructure construction occurring immediately adjacent to two sides of the site.

In the early design stages, the team performed a 3D site analysis that included sunlight modeling. This resulted in the team re-massing the building to take advantage of sunlight. Energy modeling was also employed in the beginning and end stages of the design to inform sustainable strategies and confirm predicted energy savings.

The use of BIM during design and construction allowed for a high degree of coordination and quality control among the team, and effectively shortened the construction schedule by allowing for “just-in-time” delivery of design elements.

The project team, which colocated during both design and construction, worked closely with user groups to develop strategies to lower the energy usages in the labs, particularly as it related to exhaust hoods and lighting strategies throughout the building. One strategy includes scheduled occupant evaluations after a settling in period.

Other Information

For CLSB, we put together a matrix of 30 Energy Efficiency and Water Efficiency Measurements to compare the following: first cost, energy or water savings, incentive dollars, LEED credits achieved, maintenance costs, and return on investment.

The matrix was used to evaluate which measures ultimately would provide the best value and should be incorporated into the project. Only measures with a life cycle cost analysis of fewer than 10 years were considered. One example is a heat recovery system for lab ventilation air, which had a 5.9-year payback and resulted in an annual operating savings of $33,000. Another example was the incorporation of a rainwater reuse system that resulted in a Systems Development Charge reduction of $200,000. Since this was a reduction in permit costs instead of an incentive payable only at the end of the project, the timing of this reduction made it especially valuable.

Proving an invaluable tool, the matrix presented the design team with a clear path to achieving the client’s goal of LEED Platinum. Ultimately we were able to achieve LEED Platinum certification at the relatively low net cost of $200,000 – less than 0.1% of the total cost of the project.

The design, construction and owner team came together in a collaborative effort that focused on delivering a LEED Platinum project on a tight timeline with high design goals. By having the key team members from the design and construction team colocate during both design and construction, the delivery of the project was both more efficient and more sustainable by reducing travel time and resources.

The heavy use of electronic documents during design, and the reliance on all-electronic documentation during construction, is calculated to have saved the project over $1.5 million dollars in printing costs alone, highlighting a staggering paper savings. Labor savings were made by syncing the entire design and construction team member’s electronic documents automatically to the latest issued revisions. Combined with RFIs and Submittals, savings were calculated at $8.5 million. Electronic kiosks placed on-site during construction ensured that tradespersons had immediate access to electronic drawings, thereby increasing the accuracy of work in the field, and eliminating the need for paper drawings on the job site.

The use of BIM by all design and construction team members allowed for careful coordination of the building systems prior to construction. The ability for the subcontractors to fully rely on the 3D models allowed for trades to, for example, route a sprinkler pipe around a duct that hadn’t yet been installed in the field. This eliminated the need for later field rework and the accompanying wasted resources. Similarly, the use of BIM allowed for shop fabrication of the piping systems and ductwork, increasing the quality of the fabrication and reducing field waste.

The building operator has reported an extremely smooth transition into full operations, and an official occupant survey is scheduled to occur once the building has been in full use for six months.

Additional Images

Project Team and Contact Information

| Role on Team | First Name | Last Name | Company | Location |

|---|---|---|---|---|

| Principal in Charge | Don | Eggleston | SERA Architects | Portland, OR |

| Senior Project Leader/Manager | Alene | Davis | SERA Architects | Portland, OR |

| Project Architect | George | Hager | SERA Architects | Portland, OR |

| Project Technician | Becky | Epstein | SERA Architects | Portland, OR |

| Sustainable Design | Lisa | Petterson | SERA Architects | Portland, OR |

| Principal in Charge of Design | Scott | Kelsey | CO Architects | Los Angeles, CA |

| Design Principal | Paul | Zajfen | CO Architects | Los Angeles, CA |

| Project Manager for Design Team | Jonathan | Kanda | CO Architects | Los Angeles, CA |

| Designer | Fabrian | Kremkus | CO Architects | Los Angeles, CA |

| Designer | Arnold | Swanborn | CO Architects | Los Angeles, CA |

| Structural Principal | Blake | Patsy | KPFF | Portland, OR |

| Structural Project Manager | Nathan | Ingraffea | KPFF | Portland, OR |

| Structural Project Manager | Andrea | Hektor | KPFF | Portland, OR |

| Mechanical Engineer | John | McMichael | Interface | Portland, OR |

| Principal in Charge/Lead Electrical Designer | Richard | Benney | Interface | Portland, OR |

| Project Surveyor | Jack | Carlson | OTAK | Portland, OR |

| Project Civil Engineer | Mike | Peebles | OTAK | Portland, OR |

| Civil Designer | Matt | Klym | OTAK | Portland, OR |

| Landscape Partner-in-Charge | Carol | Mayer-Reed | Mayer/Reed, Inc. | Portland, OR |

| Landscape Project Manager and Landscape Architect | Jon | Dkyhuizen | Mayer/Reed, Inc. | Portland, OR |

| Signage Principal-in-Charge | Robert | Brengman | Corbin Design, Inc. | Traverse City, MI |

| Signage Project Manager | Becky | Douthitt | Corbin Design, Inc. | Traverse City, MI |

| Signage Senior Designer | Hesper | Smyth | Corbin Design, Inc. | Traverse City, MI |

| Principal Estimator | David | Hudd | AECOM | Seattle, WA |

| Estimating Lead | Trish | Drew | AECOM | Seattle, WA |

| Principal, Senior Lab Planner | Ken | DeBoer | HKS | Dallas, TX |

| Lab Planner | Diane | Kase | HKS | Atlanta, GA |

| Dental Planning Principal/Project Manager | Larry | Schnuck | Kahler Slater, Inc. | Milwaukee, WI |

| Dental Planning Project Leader | Mark | Larson | Kahler Slater, Inc. | Milwaukee, WI |

| Senior Project Geologist/Environmental Consultant | Jason | O'Donnell | Geo Design | Portland, OR |

| Principal Geotechnical Engineer | Scott V. | Mills | Geo Design | Portland, OR |

| Wind Studies, Principal & Project Director | Ron | Peterson | CPP, Inc. | Fort Collins, CO |

| Wind Studies, Director of Engineering & Project Manager | Bill | Esterday | CPP, Inc. | Fort Collins, CO |

| Traffic Engineering | Julia | Kuhn | Kittleson & Associates, Inc. | Portland, OR |

| Traffic Engineering | Matt | Hughart | Kittleson & Associates, Inc. | Portland, OR |

| Owner's Rep Project Executive | Mike | Day | DAY CPM | Beaverton, OR |

| Owner's Rep Project Manager | Paul | Smith | DAY CPM | Beaverton, OR |

| Owner's Rep Associate Project Manager | Henry | Alaman | DAY CPM | Beaverton, OR |

| Owner's Rep Project Manager | Doug | Garland | DAY CPM | Beaverton, OR |

| Equipment Coordinator | Steve | Eirschele | ECS | Seattle, WA |

| Commissioning Agent | Ken | Toombs | Toombs | Highlands Ranch, CO |

| Special Inspections | Aaron | VanderPol | MAYES Testing | Portland, OR |

| Envelope Consulting Project Manager and Field Technician | John | Duncan | Morrison Hershfield | Portland, OR |

| Envelope Consulting BECx Technical Lead | Claude | Louvouezo | Morrison Hershfield | Portland, OR |

| Project Executive | Dustin | Liljehorn | JE Dunn | Denver, CO |

| Senior Project Manager | Mike | Custer | JE Dunn | Portland, OR |

| Engineering Services Manager | Wade | Snyder | JE Dunn | Portland, OR |

| Senior Superintendent | Butch | Fiedler | JE Dunn | Portland, OR |

Despite a challenging site for a complex university facility, the designers created a building that engages not only three university clients but also a variety of patients in an inviting fashion. To focus on rigorous sustainability with multiple stakeholders is challenging without clear leadership from the design team, and it’s obvious the design leadership had to follow through on clearly identified priorities, but this project demonstrates that even a large building with a complex program can achieve high performance. This building has a remarkable 67% of its occupants able to use public transit, cycling or walking to access the site, and it houses 400 bike parking spaces. Like the other winners this year it seems to buck the trend of over-glazed large buildings. The façade thoughtfully handles solar control and daylight harvesting.